Laser cutting is a technology that uses a laser to cut or drill material.

The process can be used to cut various materials, including metal, wood, plastics, and textiles.

Laser cutting is helpful in manufacturing applications where a high degree of accuracy is required.

So, how does laser cutting work?

How Laser Cutting Works

The laser cutting process starts with your idea.

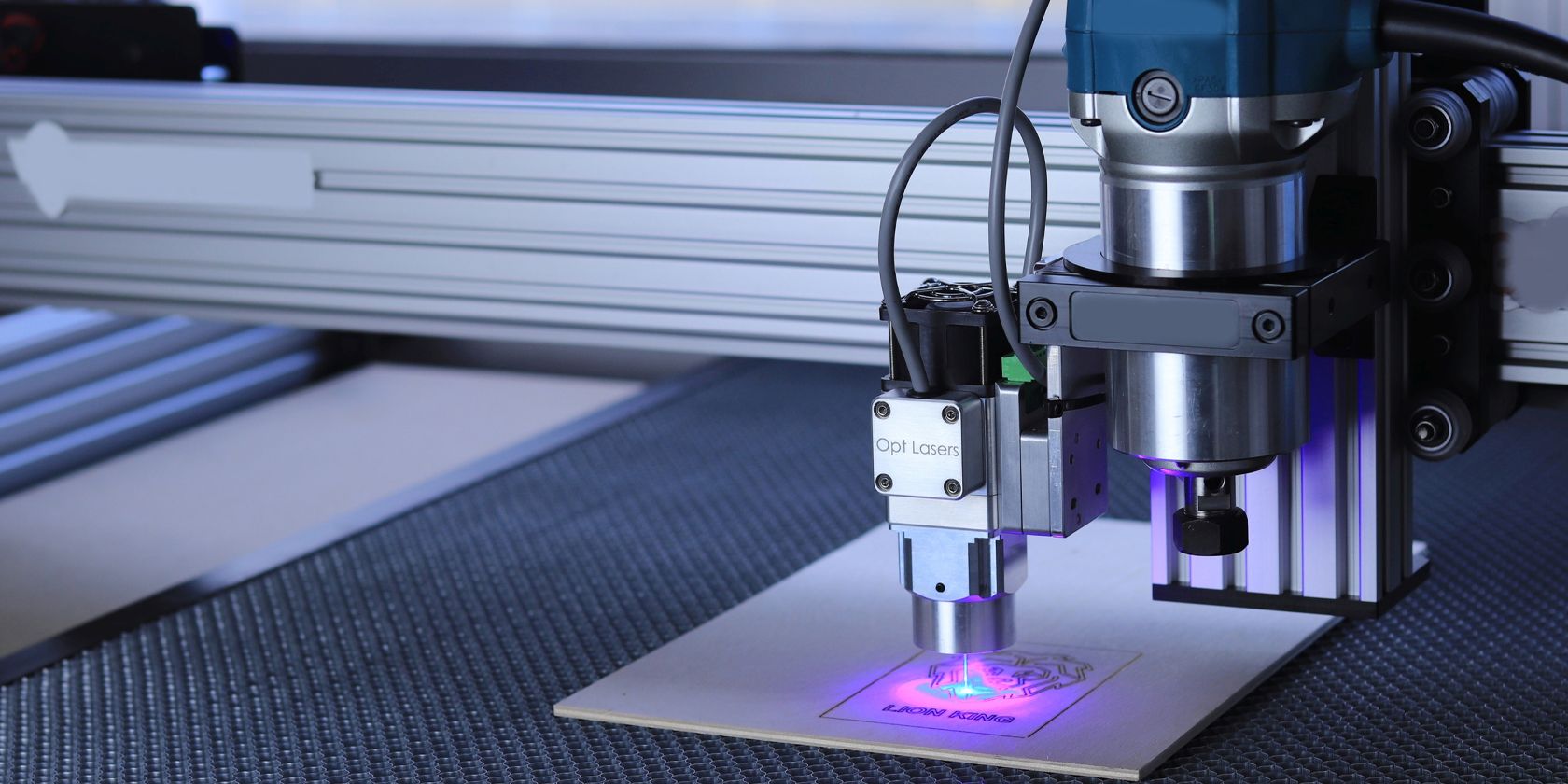

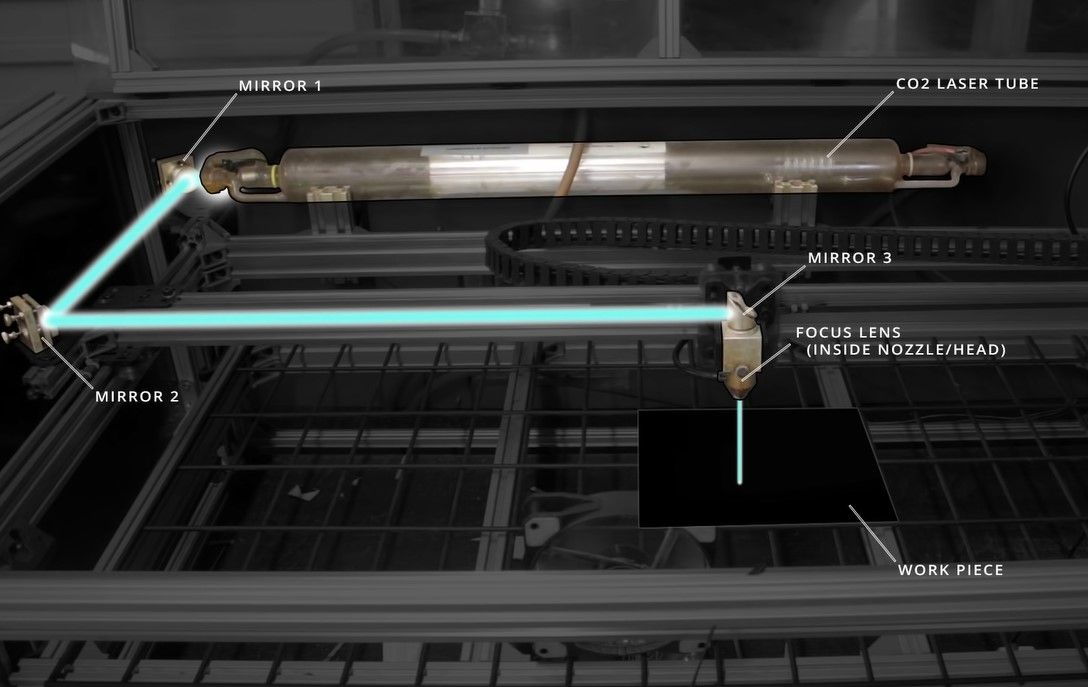

The laser cutter generates a high-powered laser beam directed on to the material using the laser head.

Image credit: Maker’sMuse/YouTube

Find outhow to prepare a G-code file.

The process will create a precise and clean cut with no burns or scorch marks.

Laser cutting is an accurate and versatile method for creating everything from small parts to complex components.

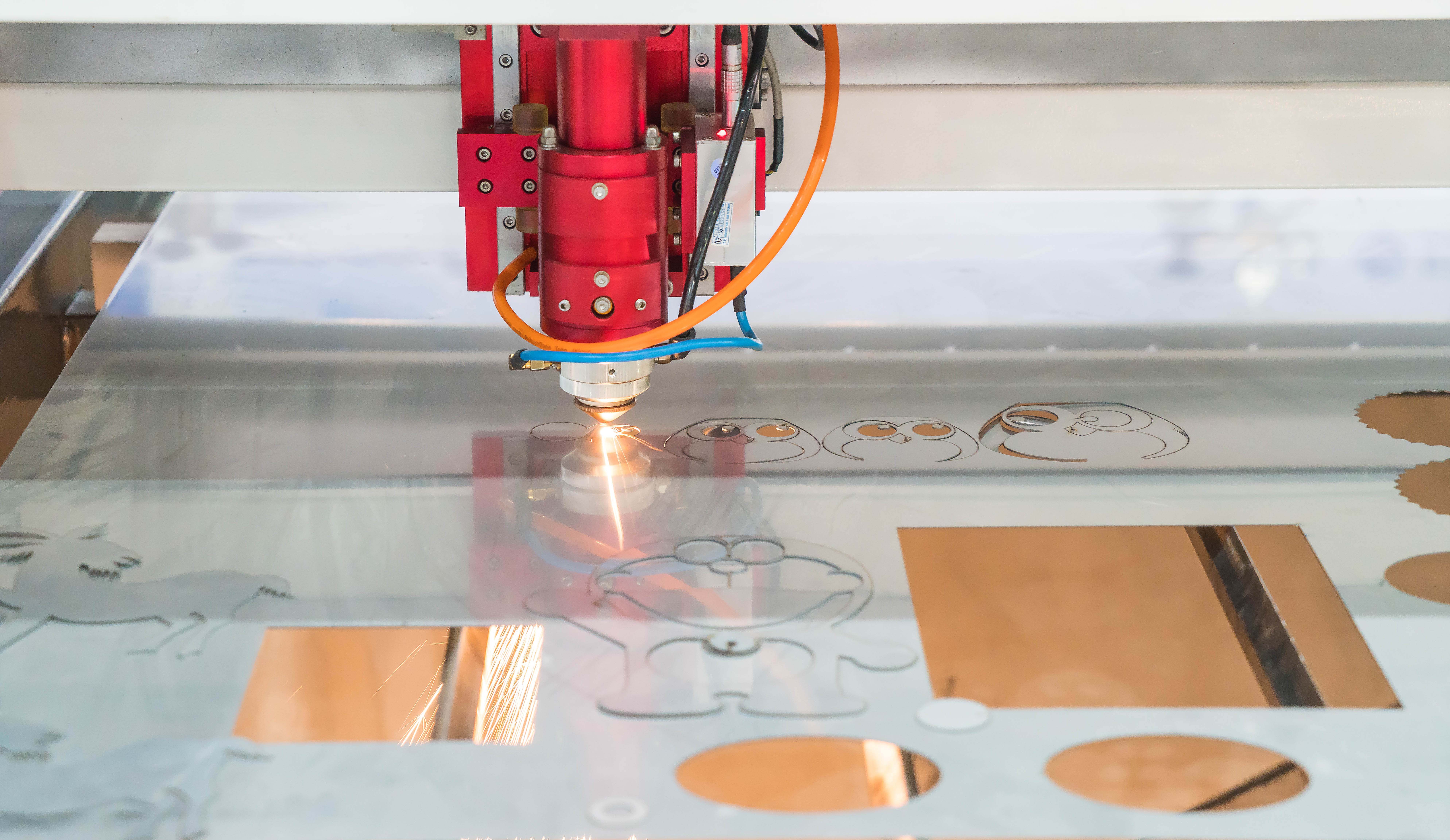

Image credit: Maker’sMuse/YouTube

Applications of Laser Cutting

In the modern world, laser cutters are an extremely useful technology.

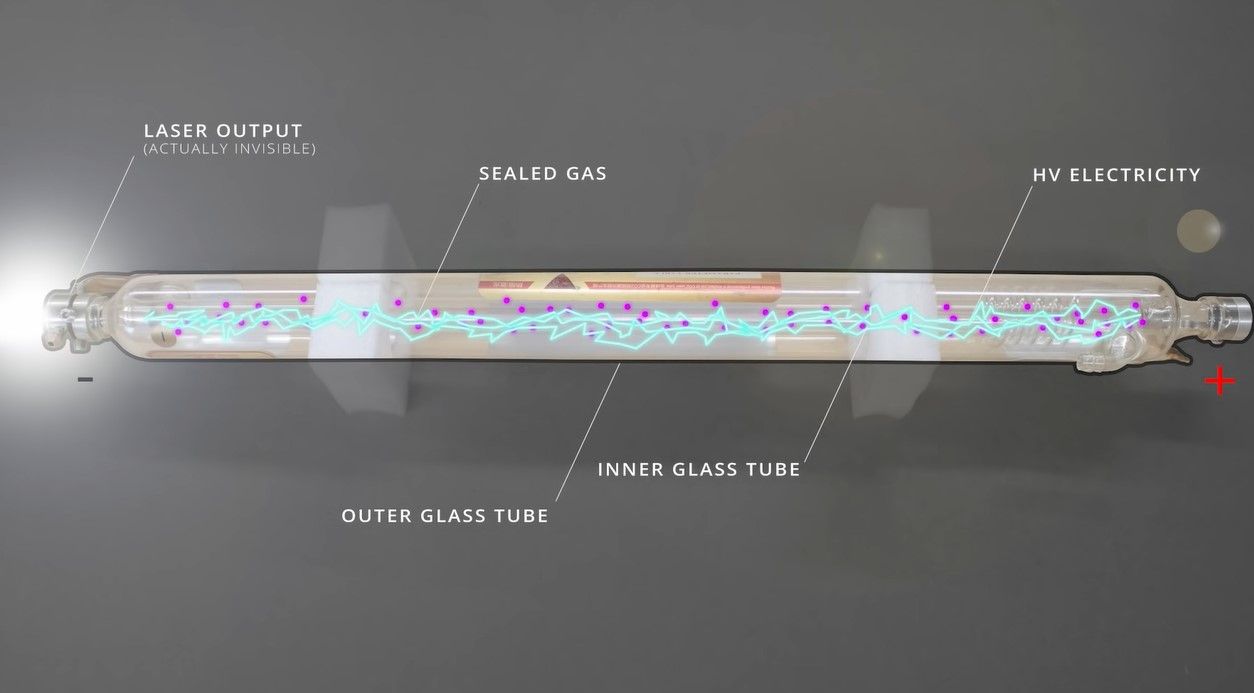

The tube is shown below.

These lasers cannot cut other materials like glass and stone; however, they can engrave on them.

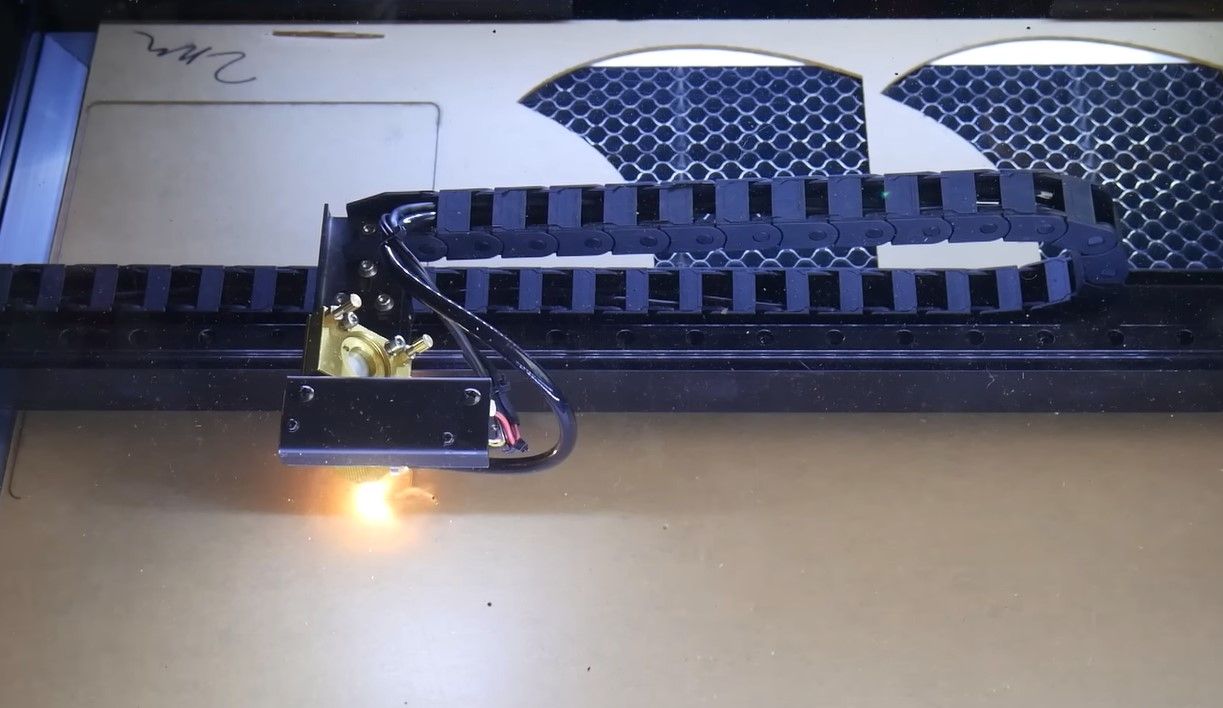

Image credit: Further Fabrication/YouTube

YAG lasers

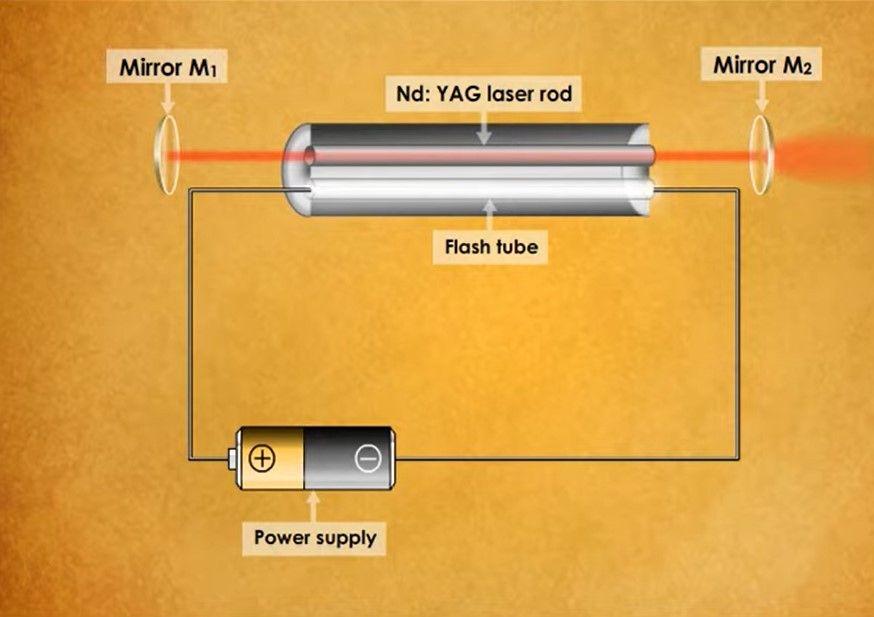

These solid-state lasers use an yttrium-aluminum-garnet (YAG) crystal as the active medium.

An external energy source like an electrical current stimulates the electrons in the crystal, producing the laser light.

The YAG contains two reflecting mirrors, m1 and m2, attached to the end, as shown below.

Image credit: Further Fabrication/YouTube

A krypton lamp or xenon flash is used to pump the signals from m1 to output through m2.

The flashlight excites ions from the power source attached below the mirrors to high energy levels.

As energy transition occurs, the photon beam is generated for laser cutting.

Image credit: Qpage/YouTube

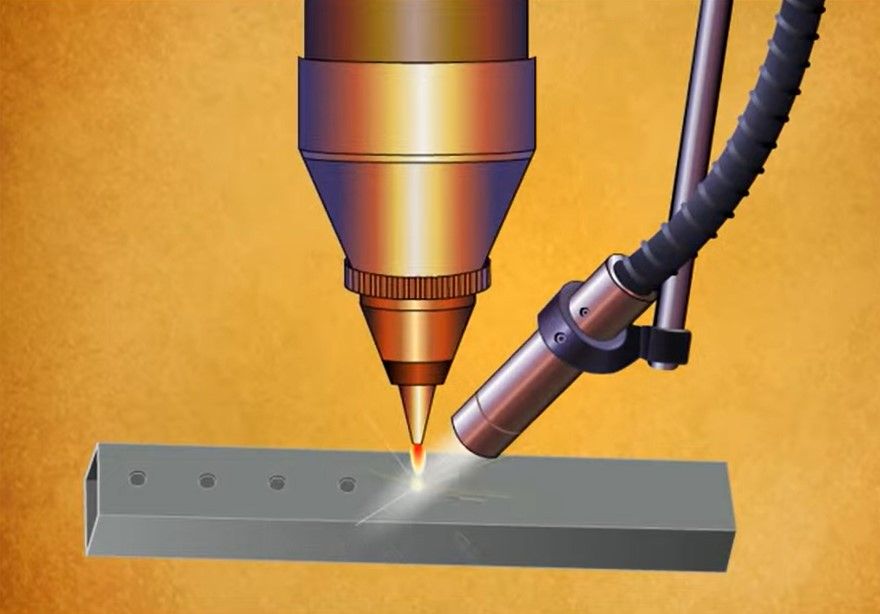

YAG lasers are usually used for drilling purposes on materials like metal.

They are distinguished from other types by their high efficiency and stability.

They are also resistant to heat and humidity damage, making them ideal for use in industrial tweaks.

Image credit: Qpage/YouTube

Fiber Lasers

Fiber lasers are primarily used forlaser engraving projectsand not explicitly for cutting.

However, you might use them for cutting thin metals, usually after several passes.

These lasers create beams using active optic fiber, which are then transmitted to the cutting head.

Image credit: Beaded Builds Co/YouTube

However, the advantages outweigh them for many applications.

With proper care and maintenance, a laser cutter can provide years of trouble-free service.

With the advancement in technology, this cutting method will continue to become more powerful and precise.

Image credit: Make or Break Shop/YouTube

Most laser cutters can cut through materials like metal with high precision.

And as it continues to become more popular, the demand for skilled workers is increasing.