Computer Aided Manufacturing (CAM) is a technology that has revolutionized the way products are designed and manufactured.

The CAM software takes a digital model and creates instructions for the automated manufacturing machine.

What Is Computer-Aided Manufacturing?

Computer-Aided Manufacturing (CAM) uses computer technology to simulate and facilitate the production of machines and machine parts.

CAM dates back to the 1950s when researchers explored using computers for automation and coordination of manufacturing.

CAD and CAM are closely linked since they’re both used in design and manufacturing.

Areas of Applications of CAM

CAM has significantly influenced engineering and product design over the years.

CAM is versatile and has been adopted in many engineering and design fields.

Product Design and Prototyping

Product design is one of the areas where CAM plays a critical role.

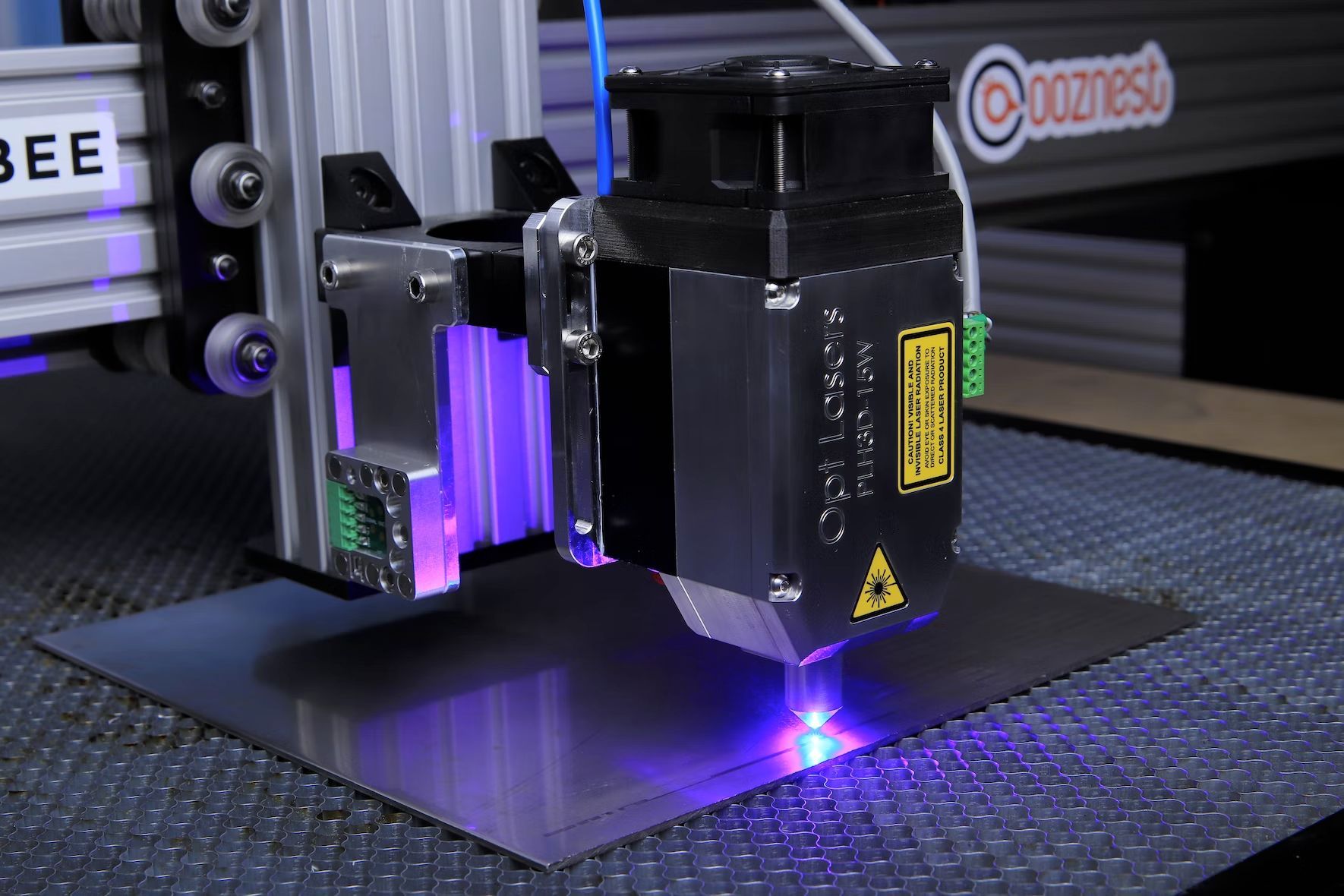

Machining and Production

CAM is also helpful in machining, machine parts, and component production.

CAM can achieve quality control and inspection through visual inspections against other models to identify deviations and defects.

Disadvantages of CAM

CAM might be attractive, but only suitable for some cases.

There are some other factors you want to consider.

Popular CAM Software

There are many CAM software in the market with varying features and functionalities.

Here are the three most popular CAM software you could use.

you might Use CAM for 3D Printing

you might use CAM for 3D printing in many ways.