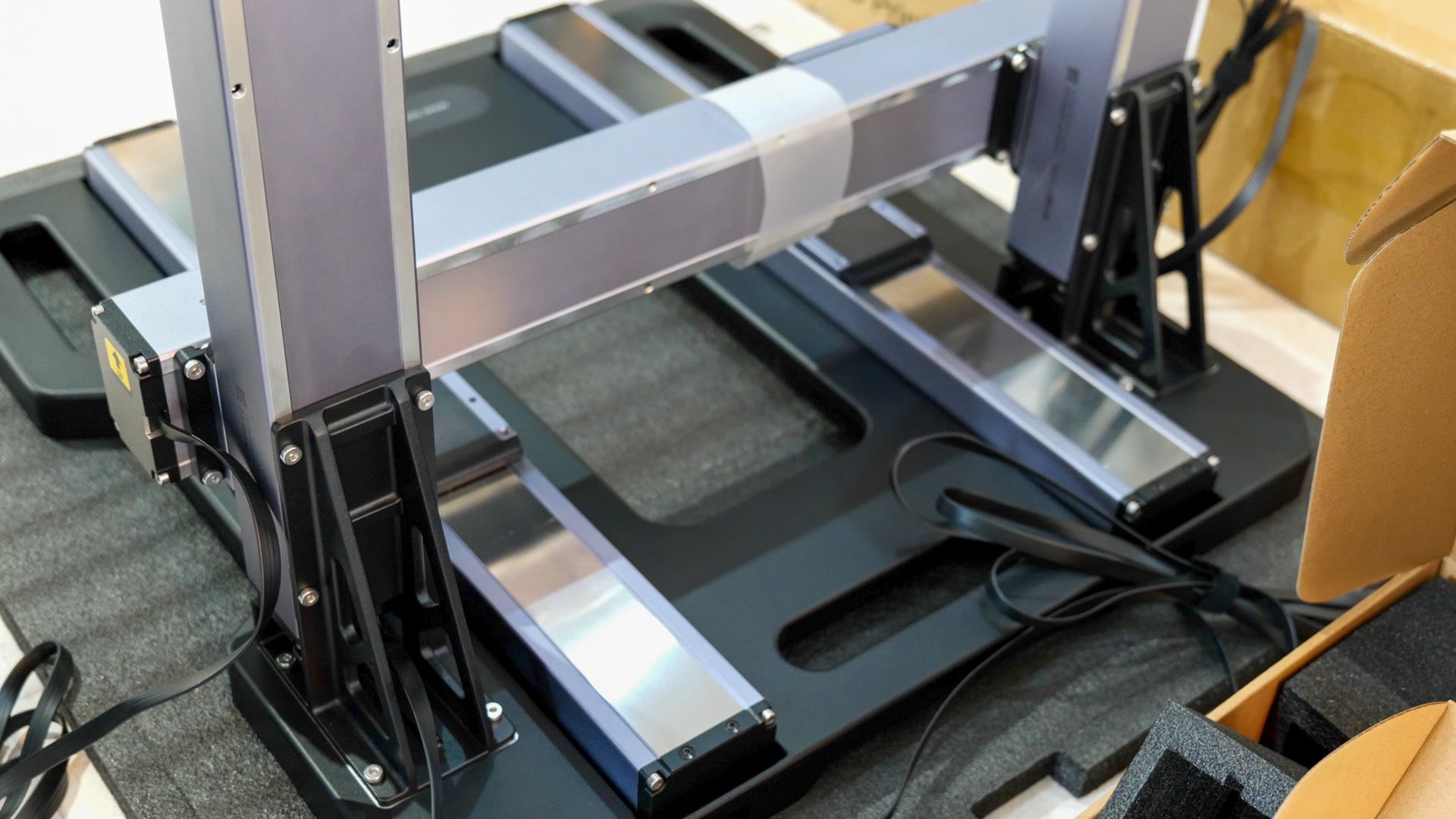

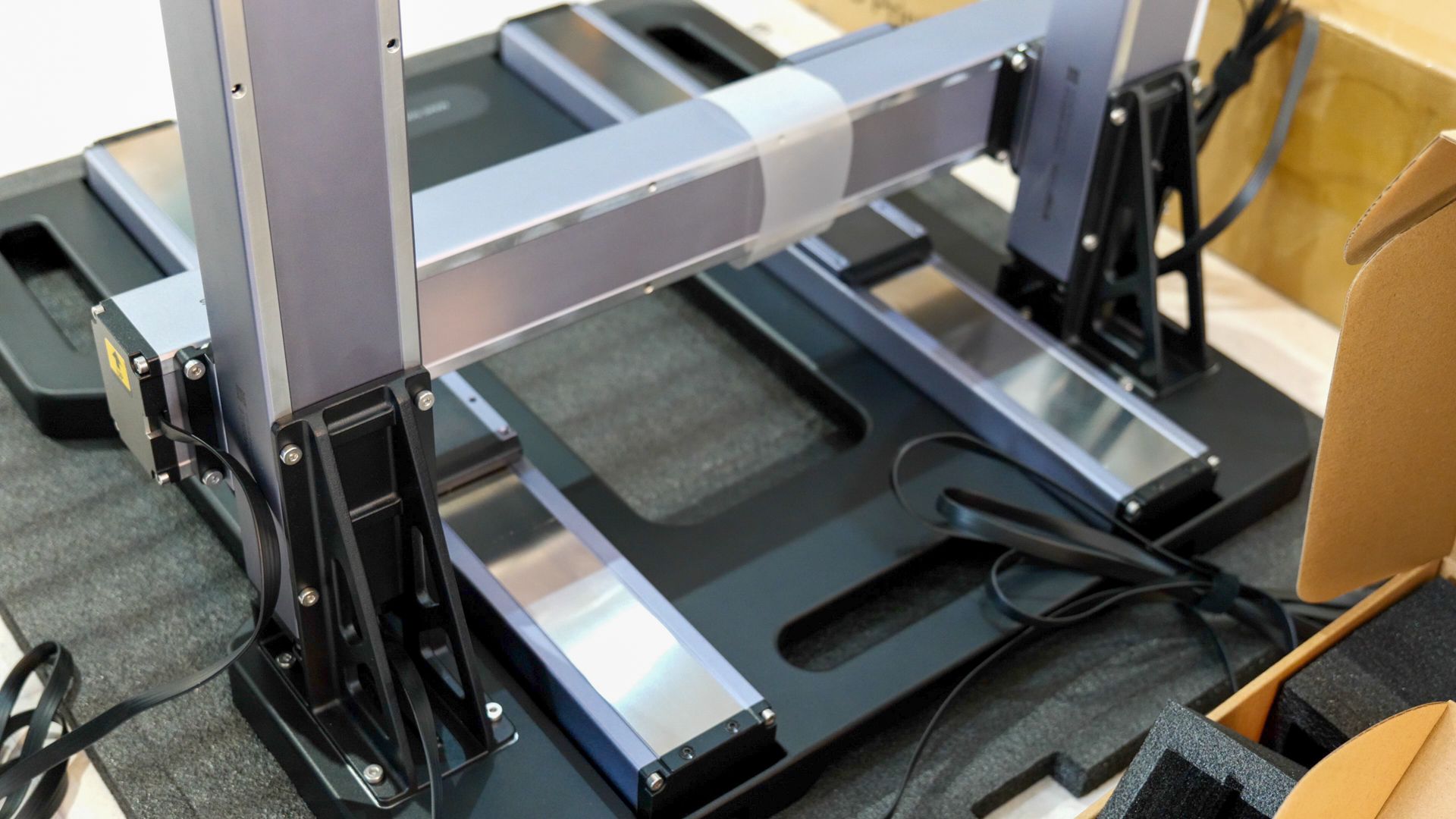

But it is a massive delivery in two bundleseach weighing over 30kg.

You might be blown away by the sheer number of boxes here.

Another box, measuring 4 x 3 x 6 inches, contains a single pair of plastic safety goggles.

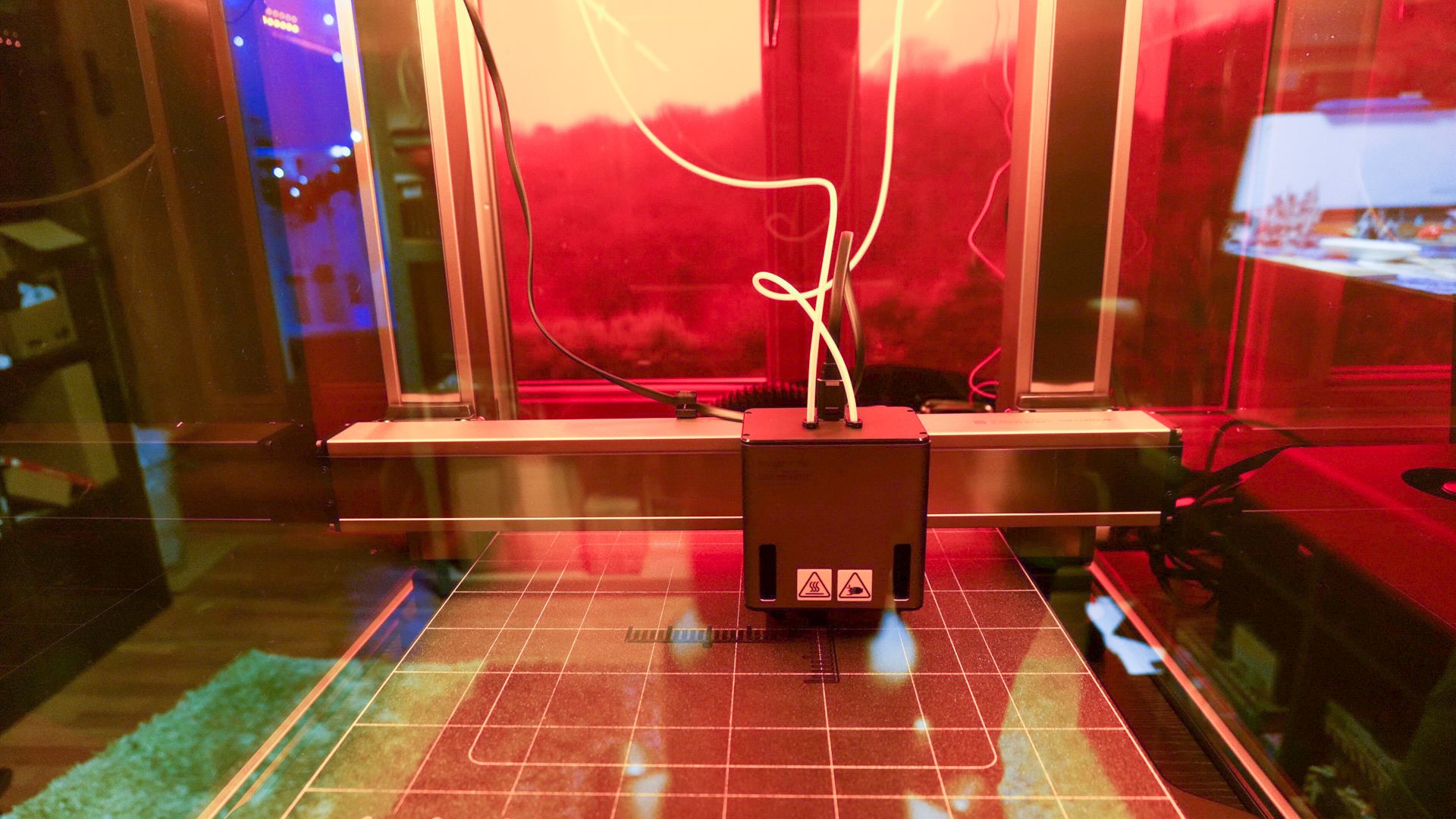

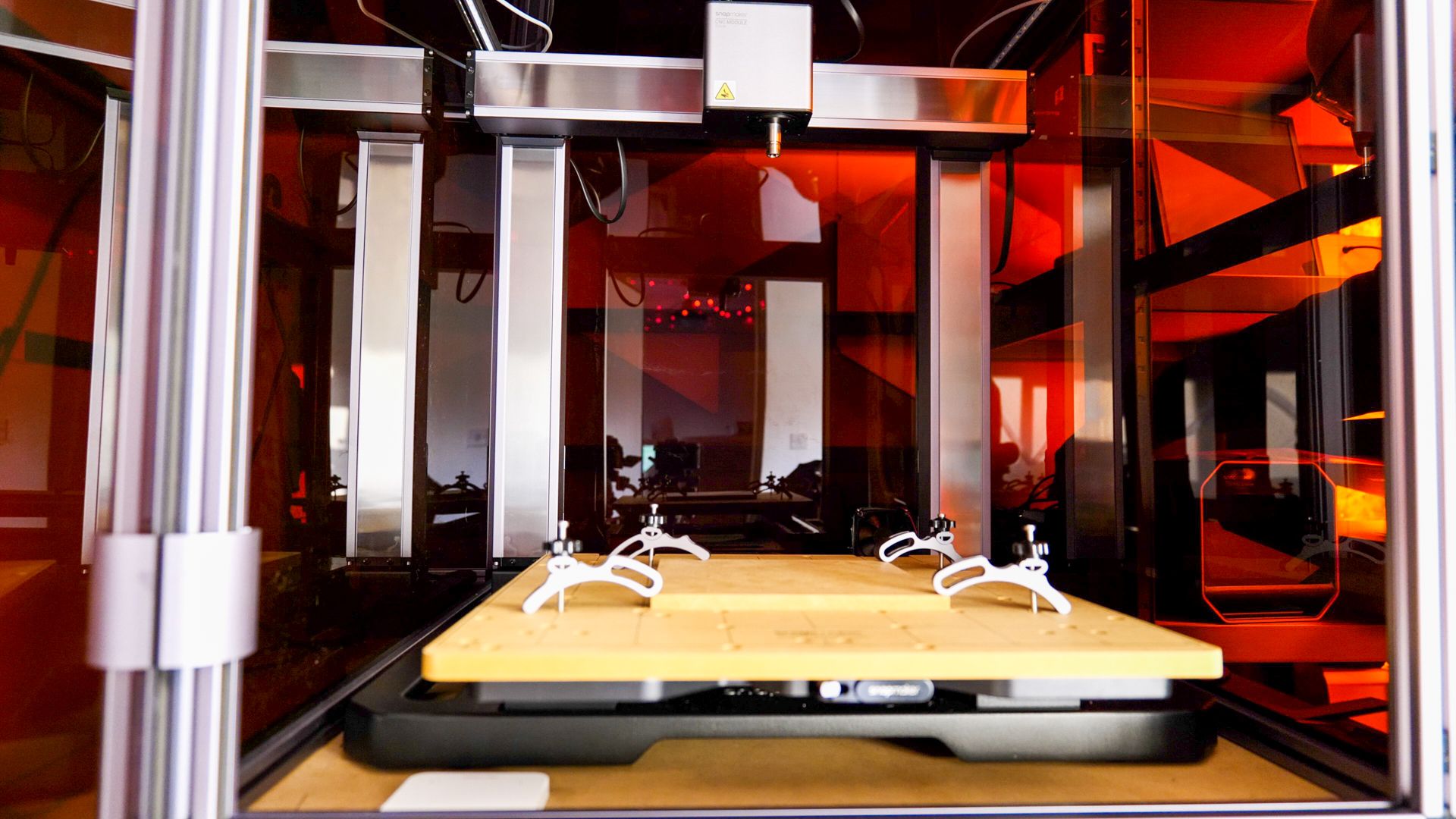

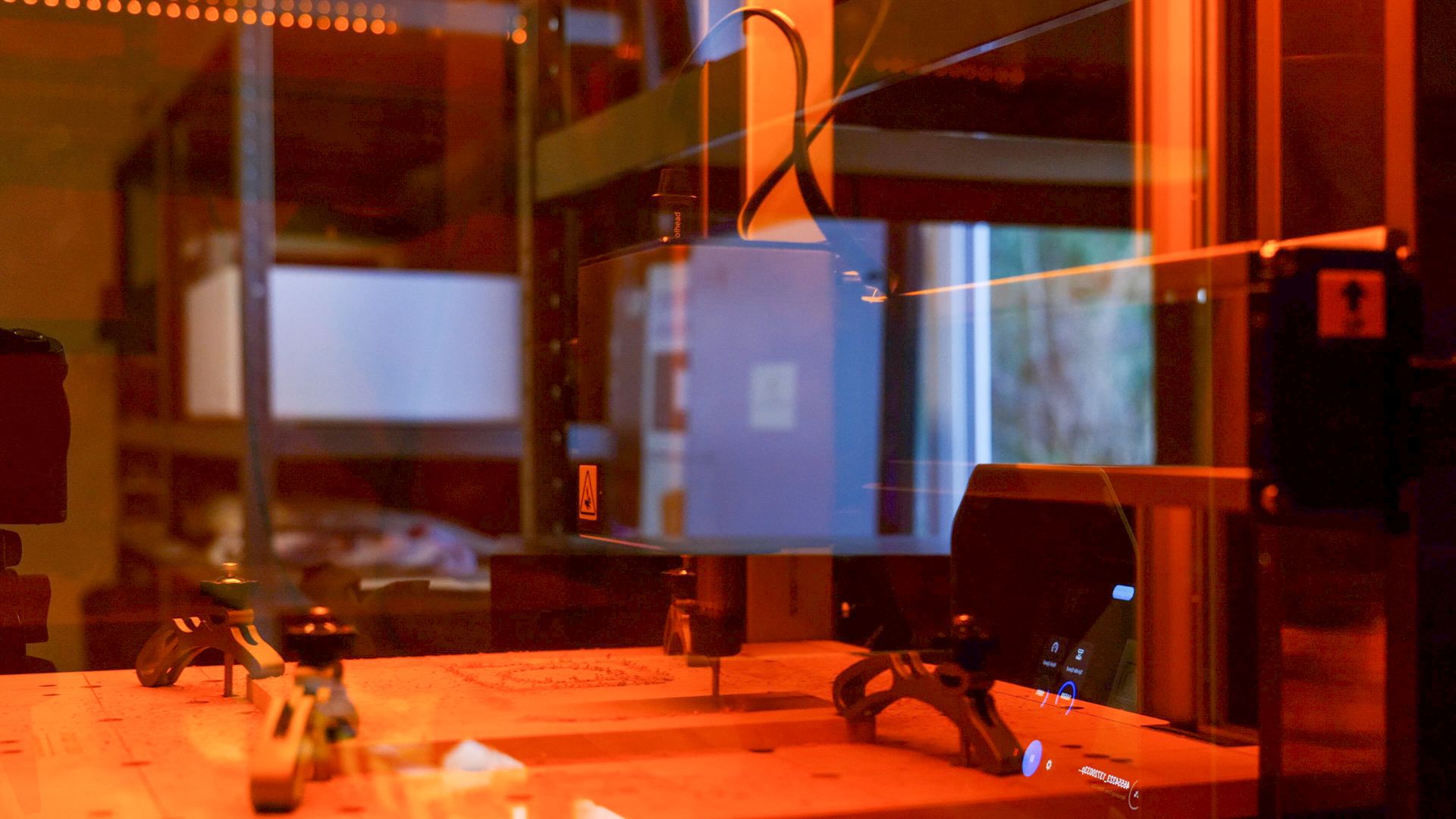

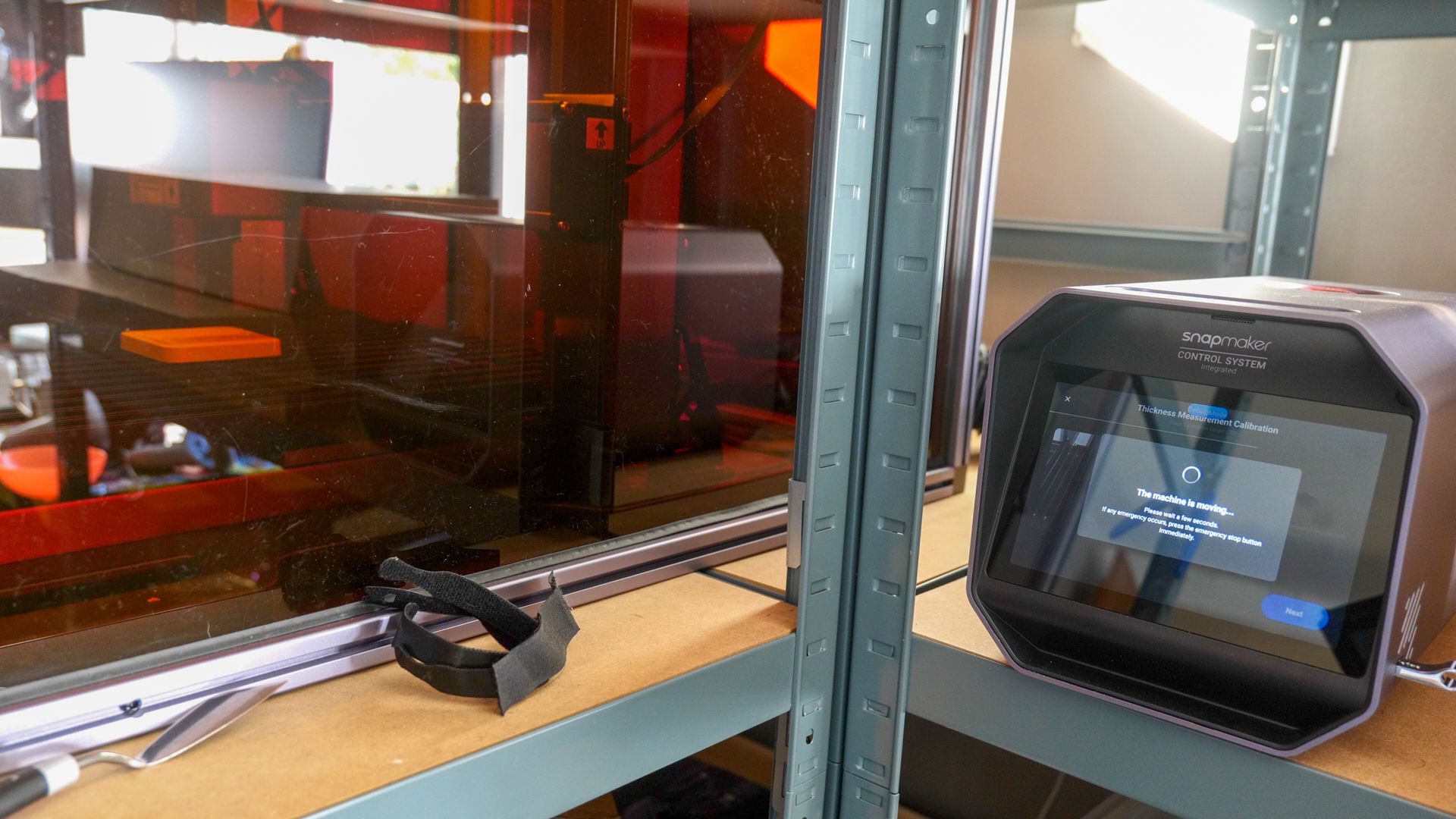

Each axis is controlled by custom linear modules, which are also enclosed with no exposed beams or bearings.

It’s a really innovative design.

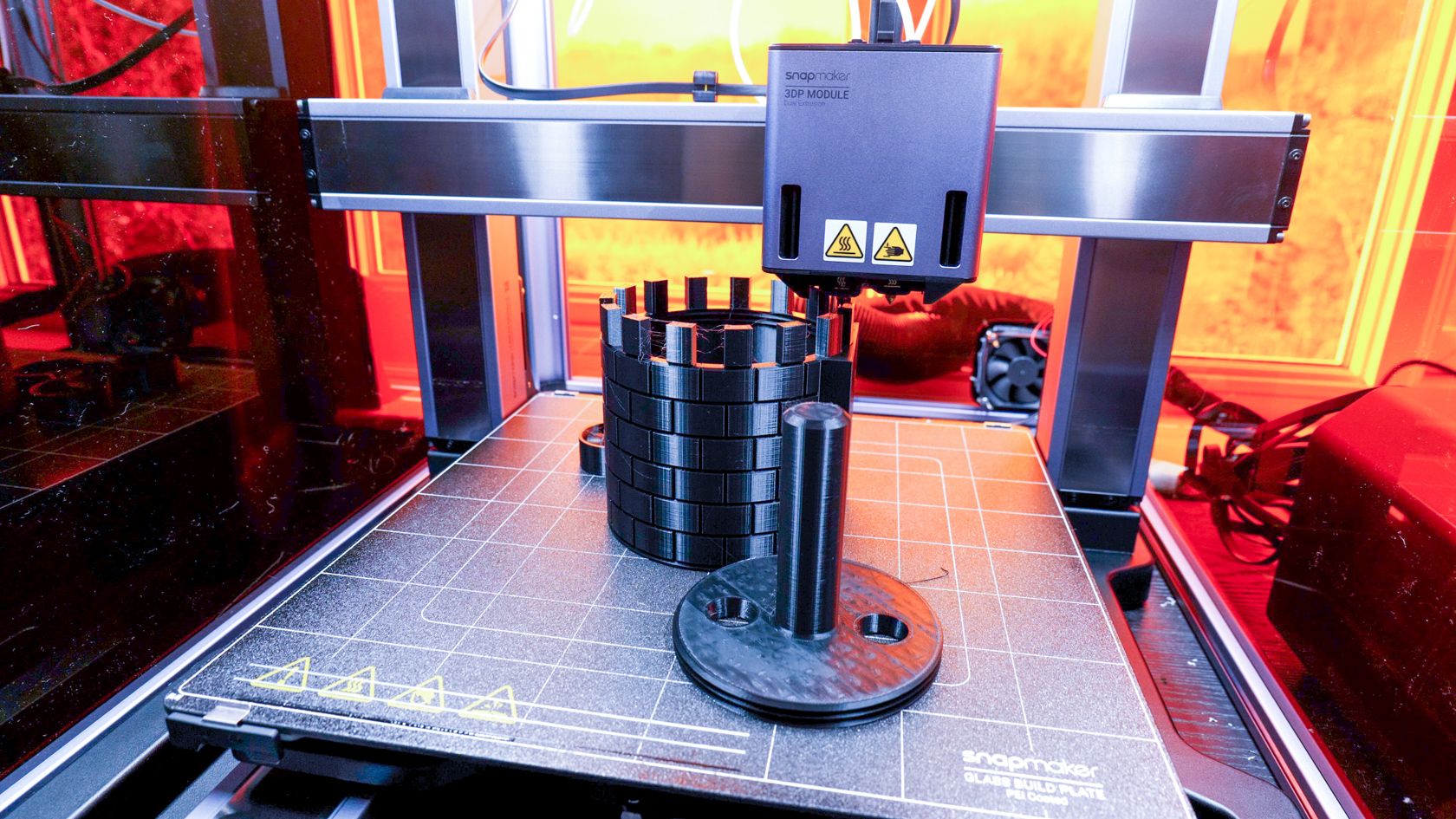

The actual build area is enormous at 40cm (15.75 inches) cubedenough to print a full human-sized helmet.

But as well as a large build area, a brown acrylic enclosure covers all the moving parts.

It’s so big in fact that I had to completely rearrange my office workshop to accommodate it.

The total weight of the machine and control box when built is around 52kg (115 lbs)!

Despite the marketing on the Snapmaker website, this isn’t even remotely “desktop-sized”.

So despite the marketing images showing it enclosure-less and desktop-size claims, I don’t think that’s viable.

But it’s not just the enclosure you’ll need to accommodate.

Now, this is far more advanced than your average 3D printer control module.

With two entirely separate extruders, the Artisan eliminates that problem and makes dual-color printing effortless.

However, there’s nothing fancy about filament storage on the Artisan.

It’s just a metal tube on the outside of the case.

Our Artisan shipped with a black filament and some white breakaway filament for testing.

It also costs two to three times that of regular PLA.

Subsequent tests a few weeks later all proved unsuccessful, with various extrusion issues.

One small feature I appreciated was the option not to heat the entire print bed.

For small objects, you only need the middle heated, so that saves on the power bill.

Once integrated with the native Luban software, you’ll be able to print over Wi-Fi.

The PEI-coated glass bed is going to give the best results and is easiest to work with.

Leveling is superb, and I had gorgeous first layers with no warping.

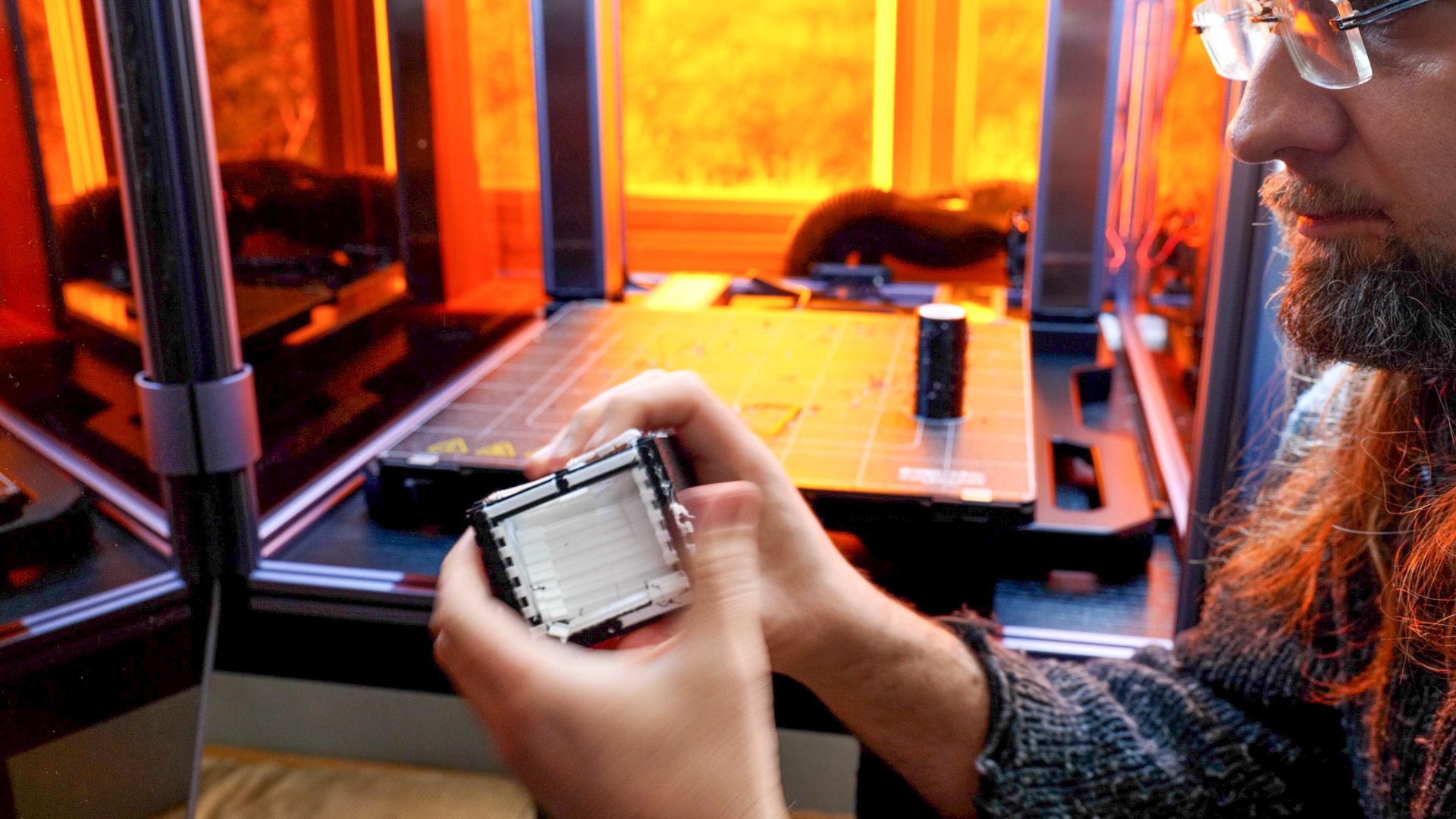

My first print was a LEGO-compatible Christmas ornament, using the breakaway filament for support.

It didn’t come out well at all, as expected.

Finally, I tried PETG, and the results were much more frustrating.

This might be a case of the profile not being fully fleshed out yet.

After a few hours, it would come unstuck and be knocked off.

However, this was more frustrating than I have experienced with other printers out of the box.

Overall, for 3D printing, I was very impressed, but with mixed results in some cases.

The true dual extruder system is very useful, and the print beds provided are fantastic.

First-layer adhesion was mostly excellent, except for PETG.

While I won’t say the prints were perfect, I did generally find it to be very reliable.

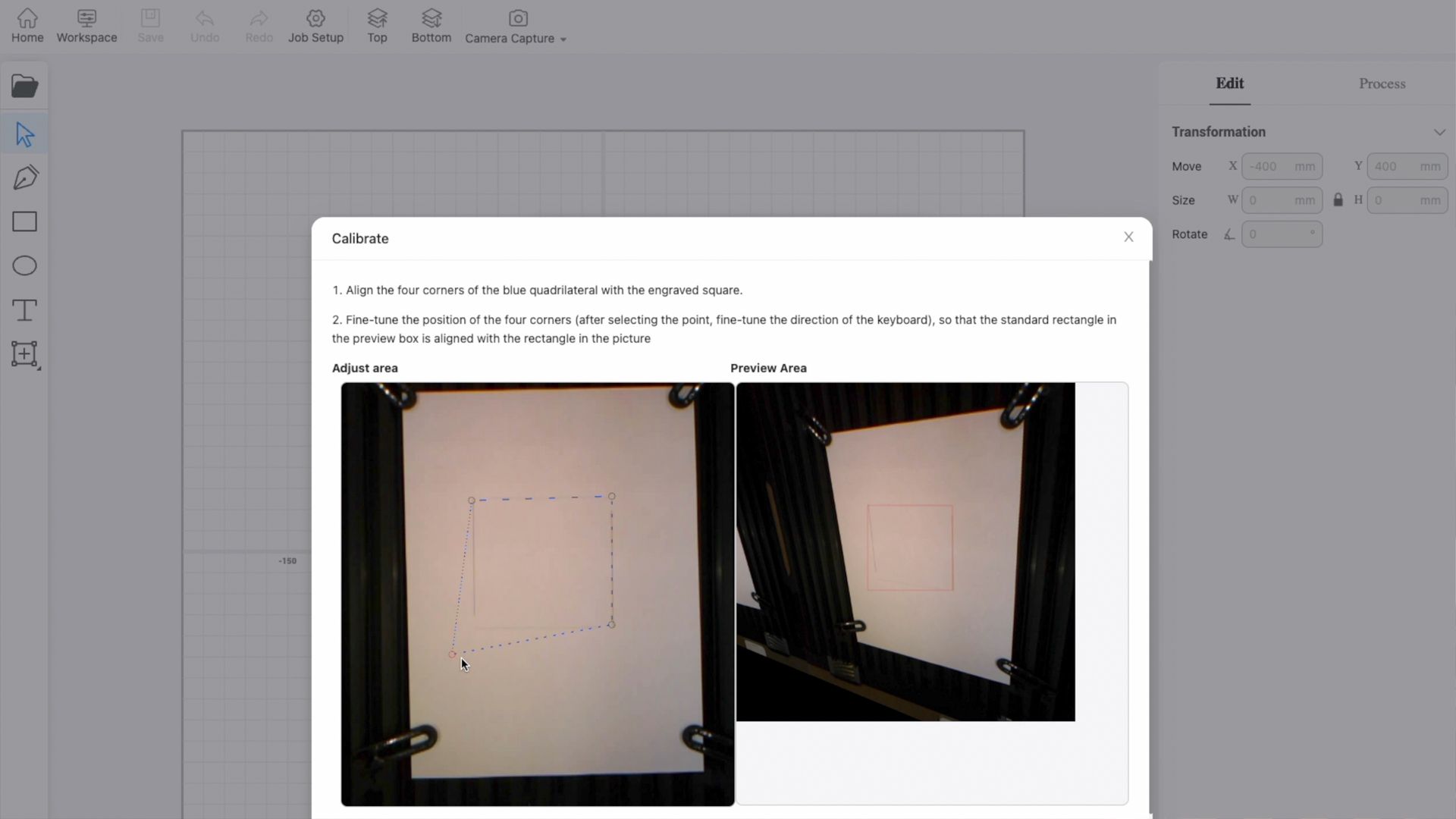

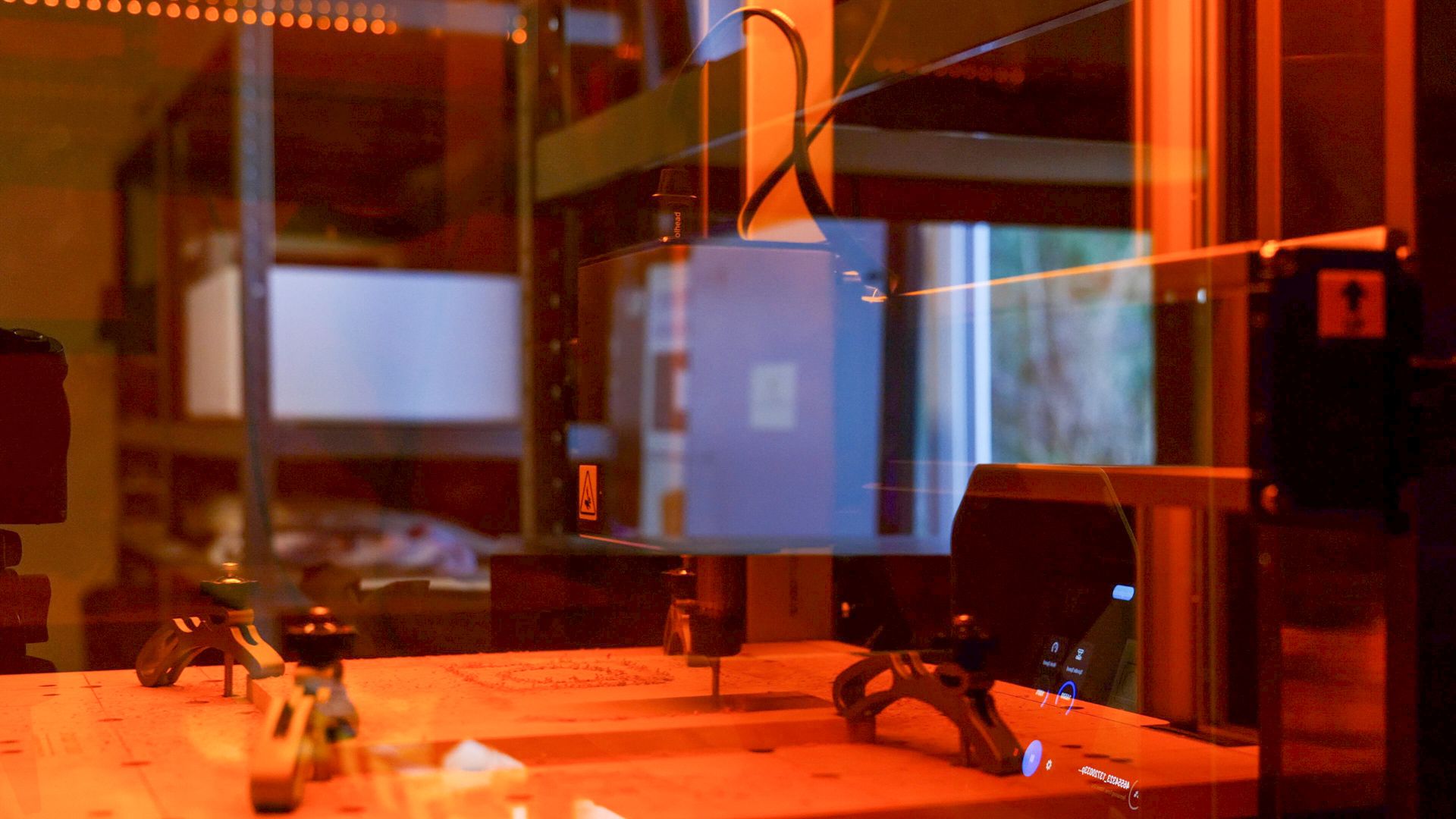

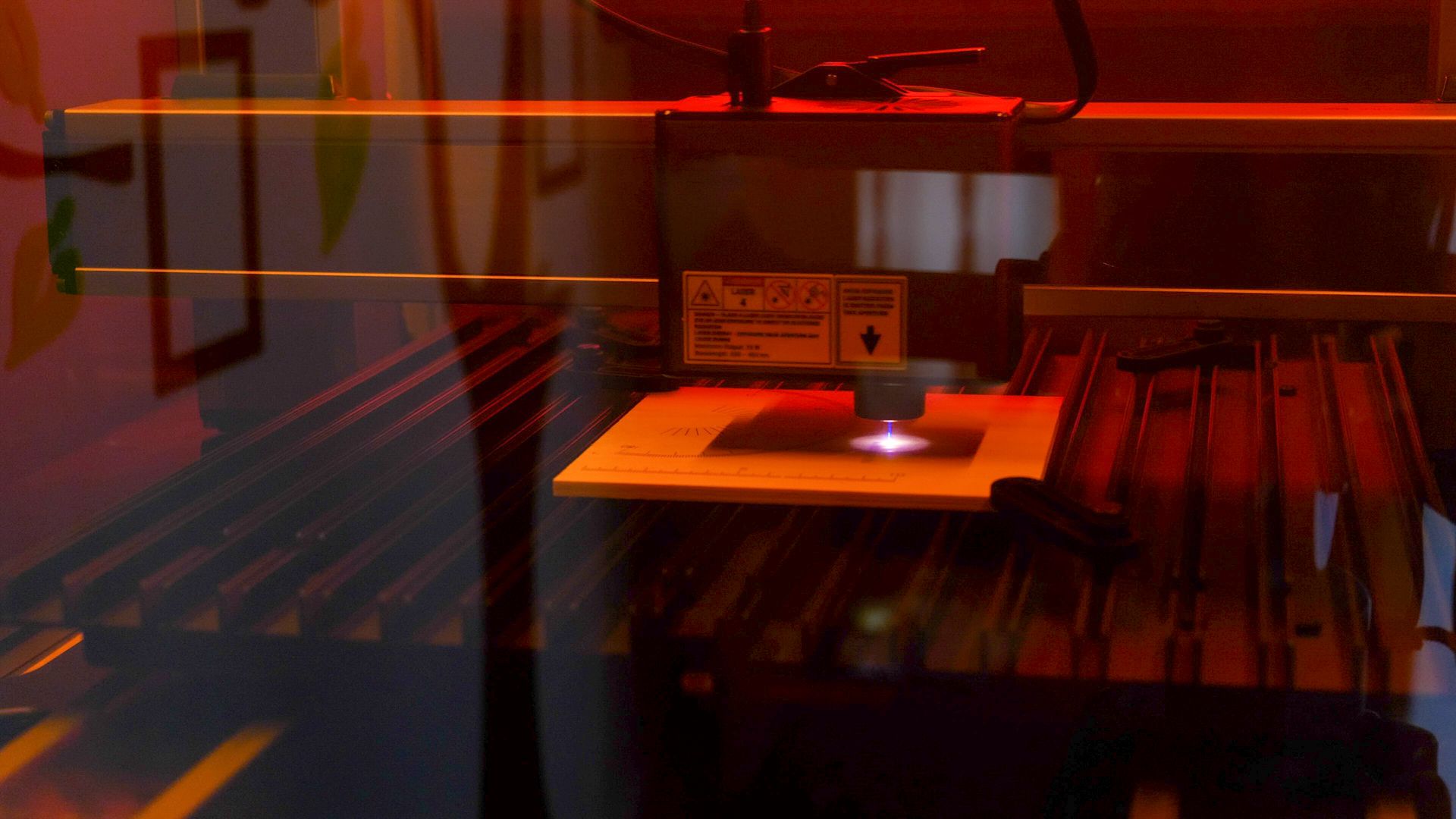

This process isn’t optional and is quite involved.

Then, you need a fix a sheet of blank paper to the build plate.

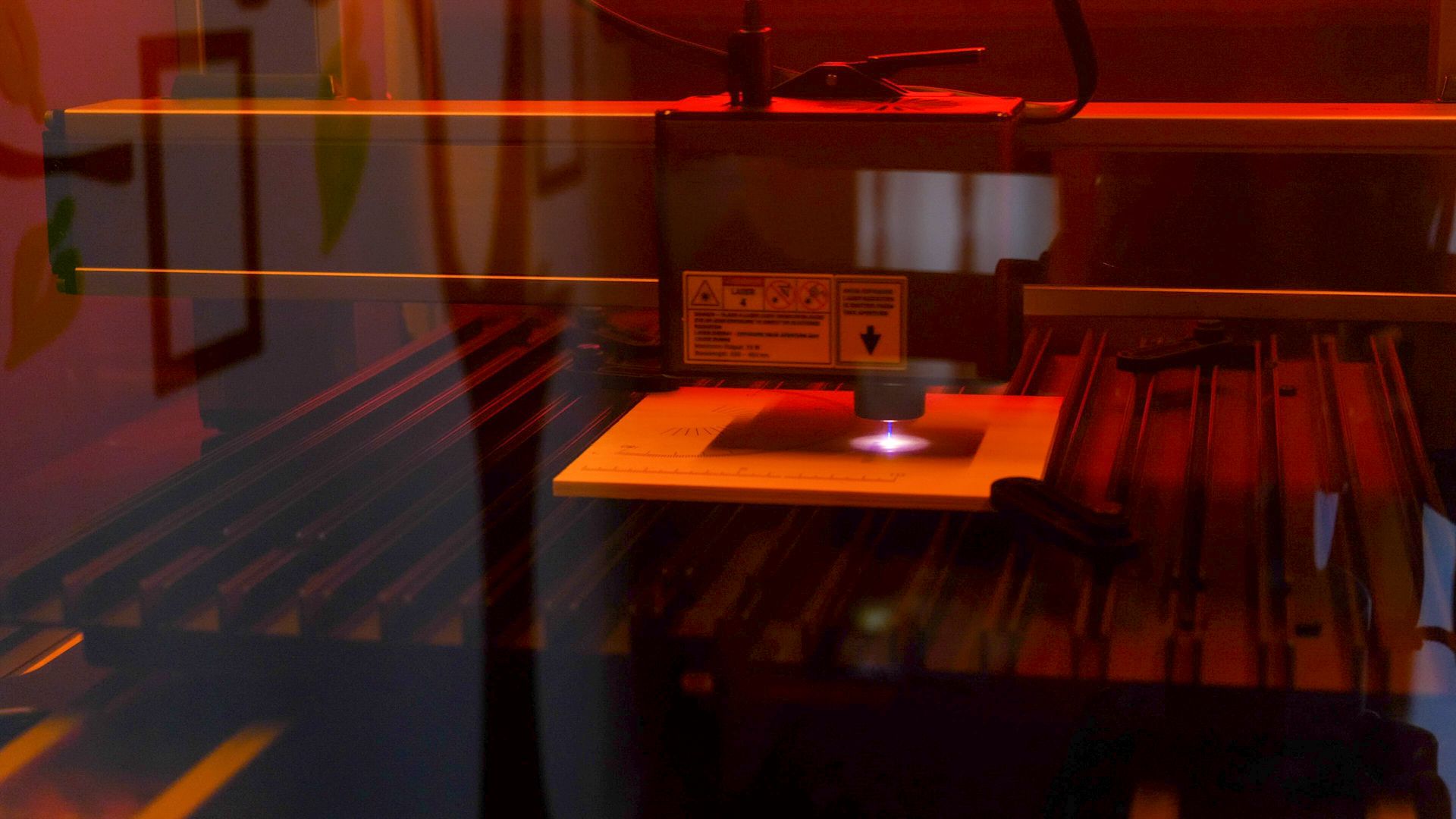

The laser results are promising, and the Artisan has built-in libraries of tweaks for engraving various materials.

The focusing is automatic, but you might also opt for manual focusing.

It shouldn’t be difficult for a 10W laser to cut this sort of acrylic, mind.

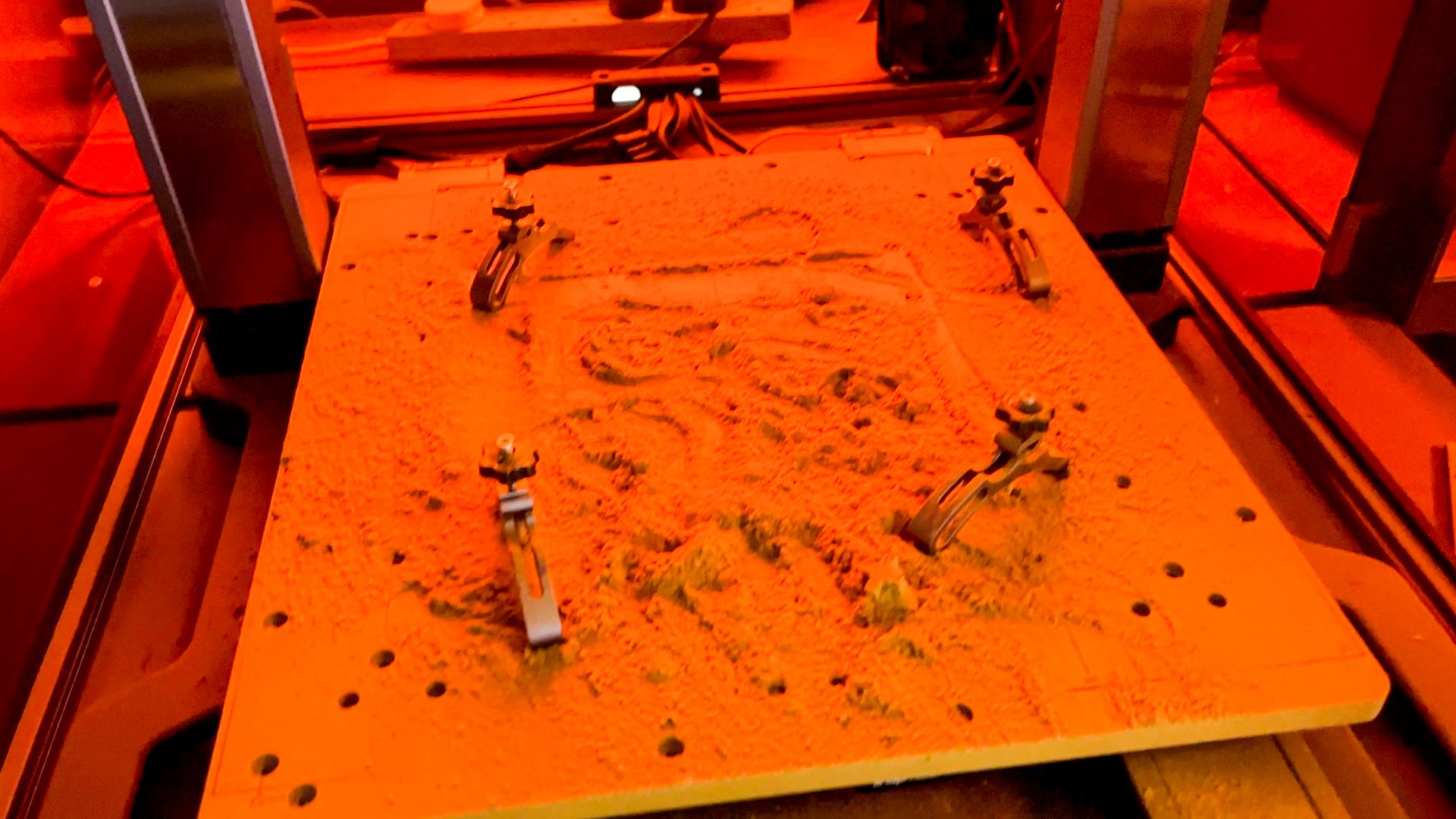

Finally, I etched a larger design into a piece of slate (80% power, 2000mm/min).

Luban also suffers from a somewhat split personality, given that it needs to handle so many different functions.

It’s a tedious process that really needs some streamlining.

Its all straightforward to set up, and unlike other tools theres no calibration; just plug it in.

you might observe with the door open, but you should wear the supplied goggles at all times.

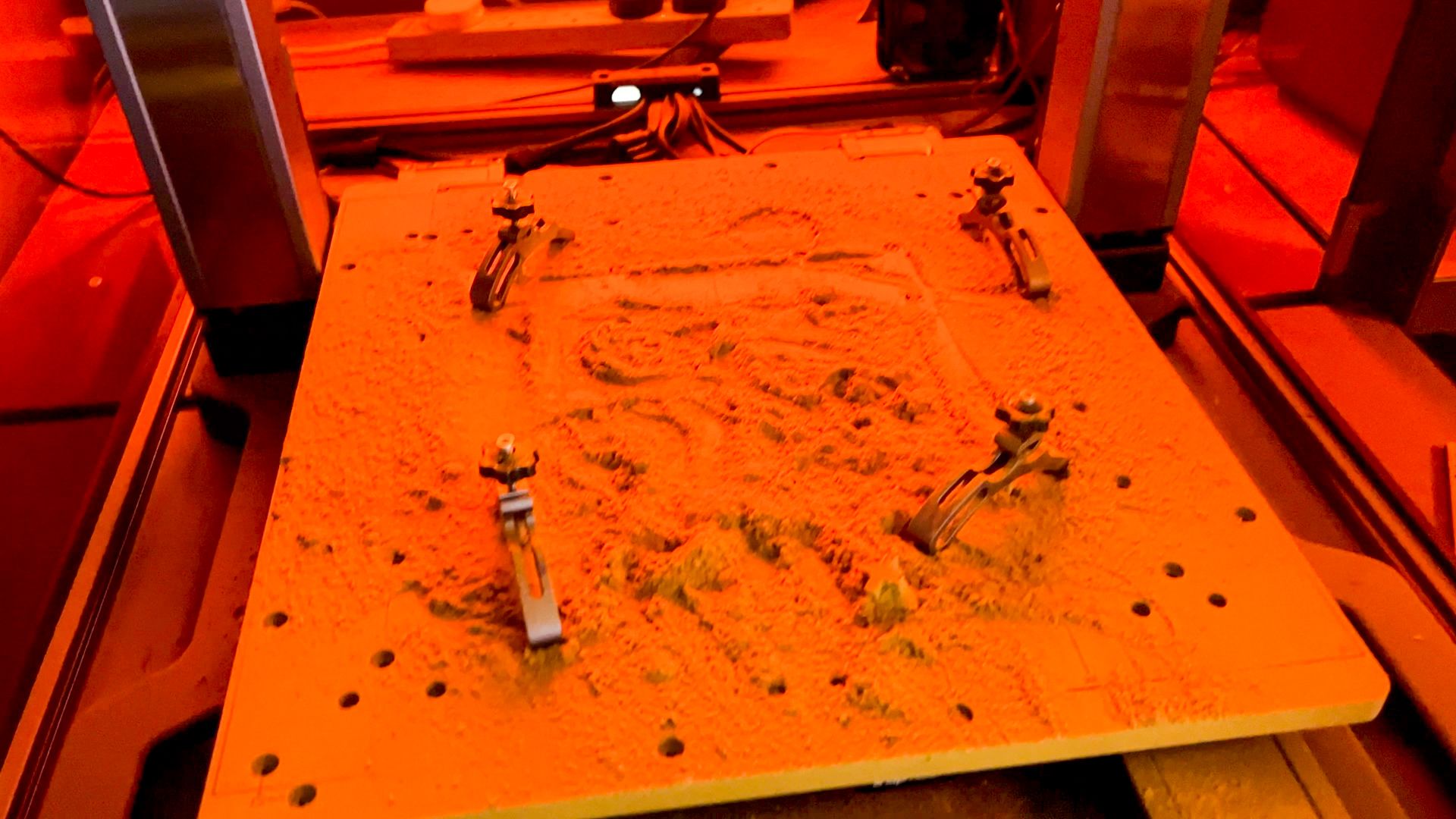

The process is subtractive, removing material each time.

You shouldn’t use the extraction fan because you’ll make more of a mess and gum things up.

So you’ll also need to invest in shop vac which is rated for dust extraction.

In terms of quality, the demo project (a puzzle cube) came out nicely.

The amount of time taken can be immense.

Lesson learned: use the v-bit for relief cutting.

The process can also be messy, so be prepared with the proper equipment and workspace.

The Ultimate Maker Machine for the Small or Home Workshop?

TheSnapmaker Artisanis not cheap, but it is an incredibly versatile machine.

However, the Snapmaker Artisan is not perfect.

The Luban software needs some improvement in the workflow.

The biggest consideration then is whether you need all of those functions.

You wouldn’t be getting nearly the same industrial build quality you have here, nor the CNC function.