Clogs can lead to wasted filament and hard-to-diagnose problems like uneven extrusion.

But before that, let’s have a look at the causes of clogging in 3D printer nozzles.

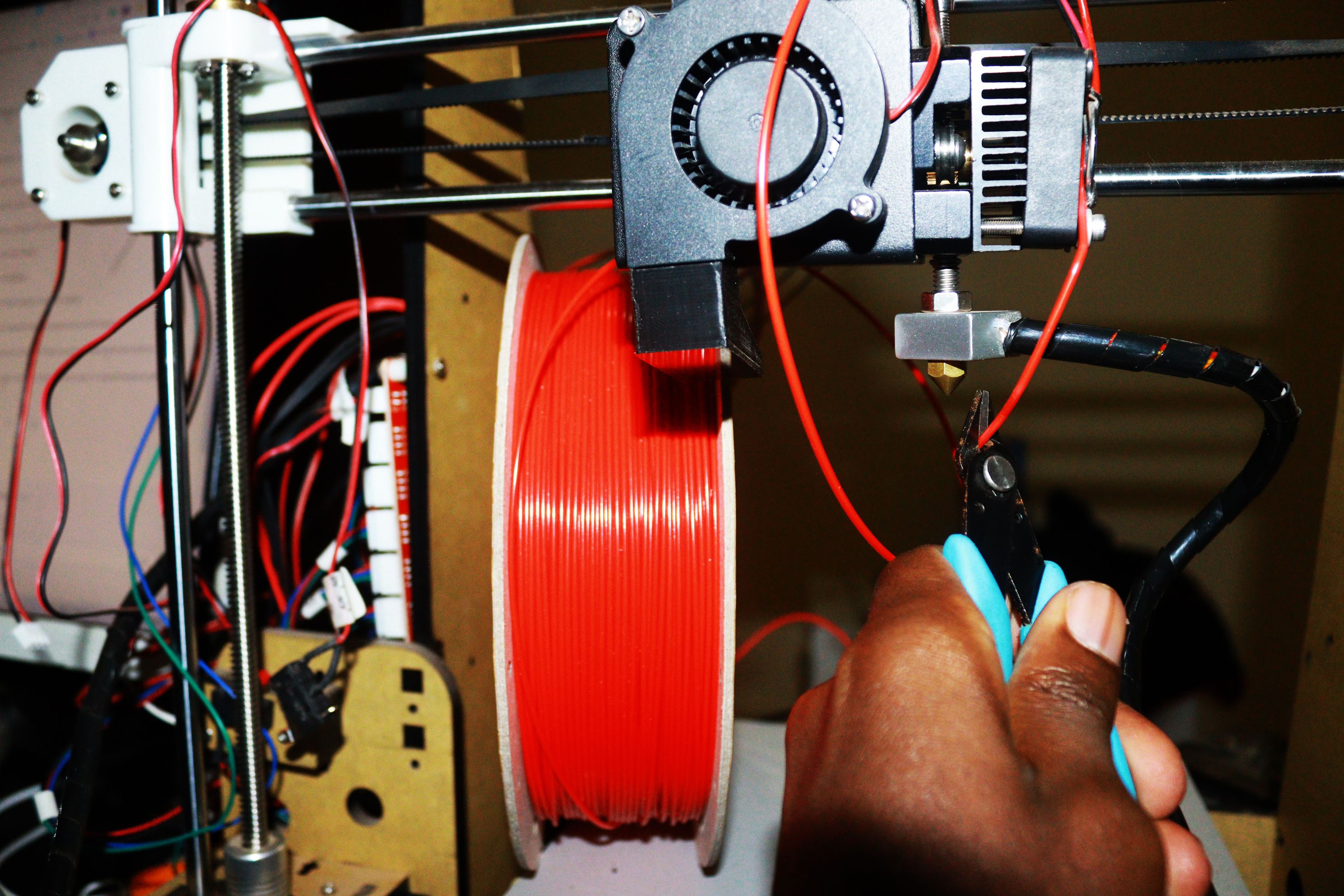

Cutting nippers require careful use to avoid damage to the nozzle or the wires.

Start by clipping away excess filament before using force for stubborn pieces of filament.

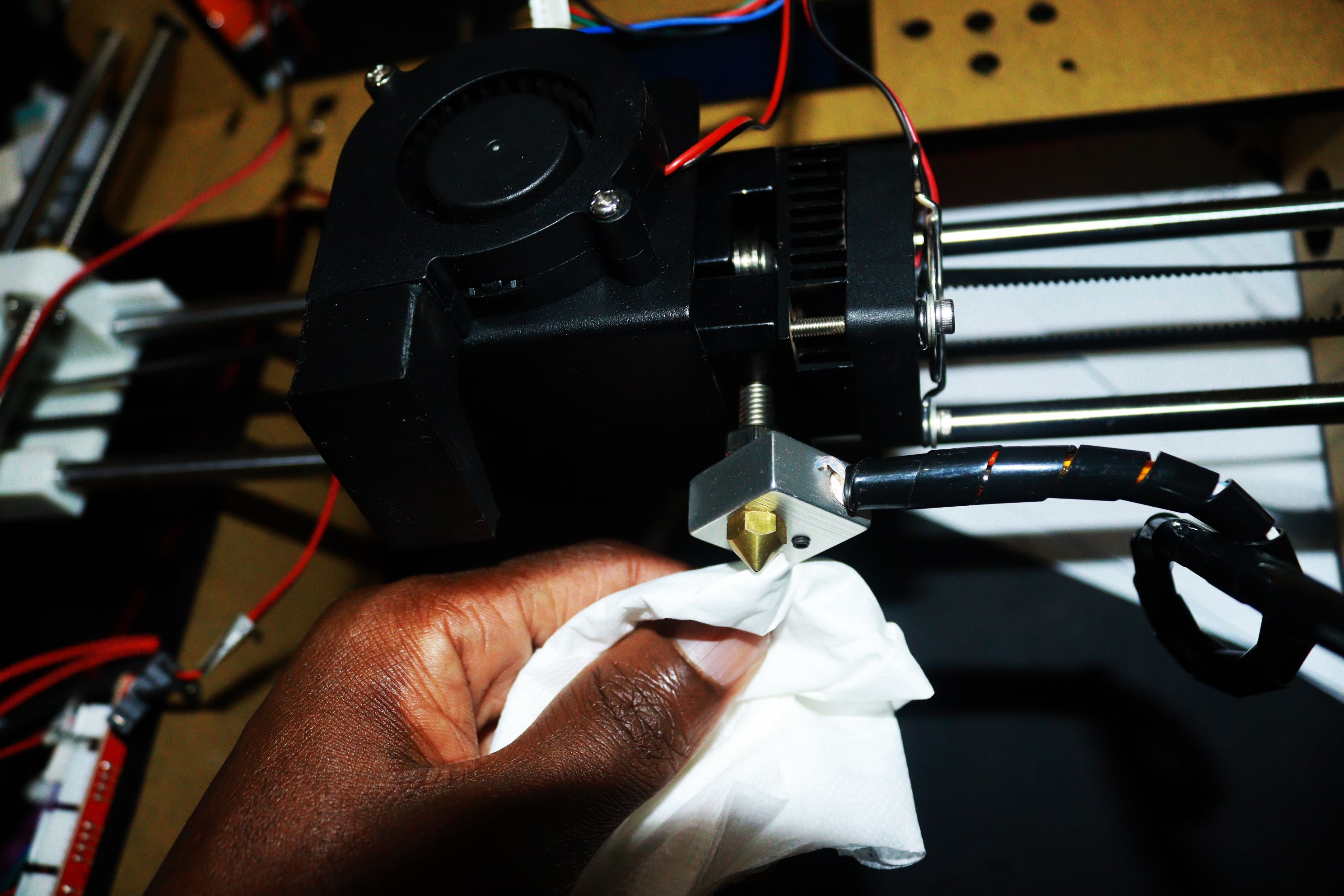

Before beginning this task, wear protective gloves and safety glasses to prevent injury from debris.

you’re able to use a soldering gun as It provides more control when melting the stuck filament.

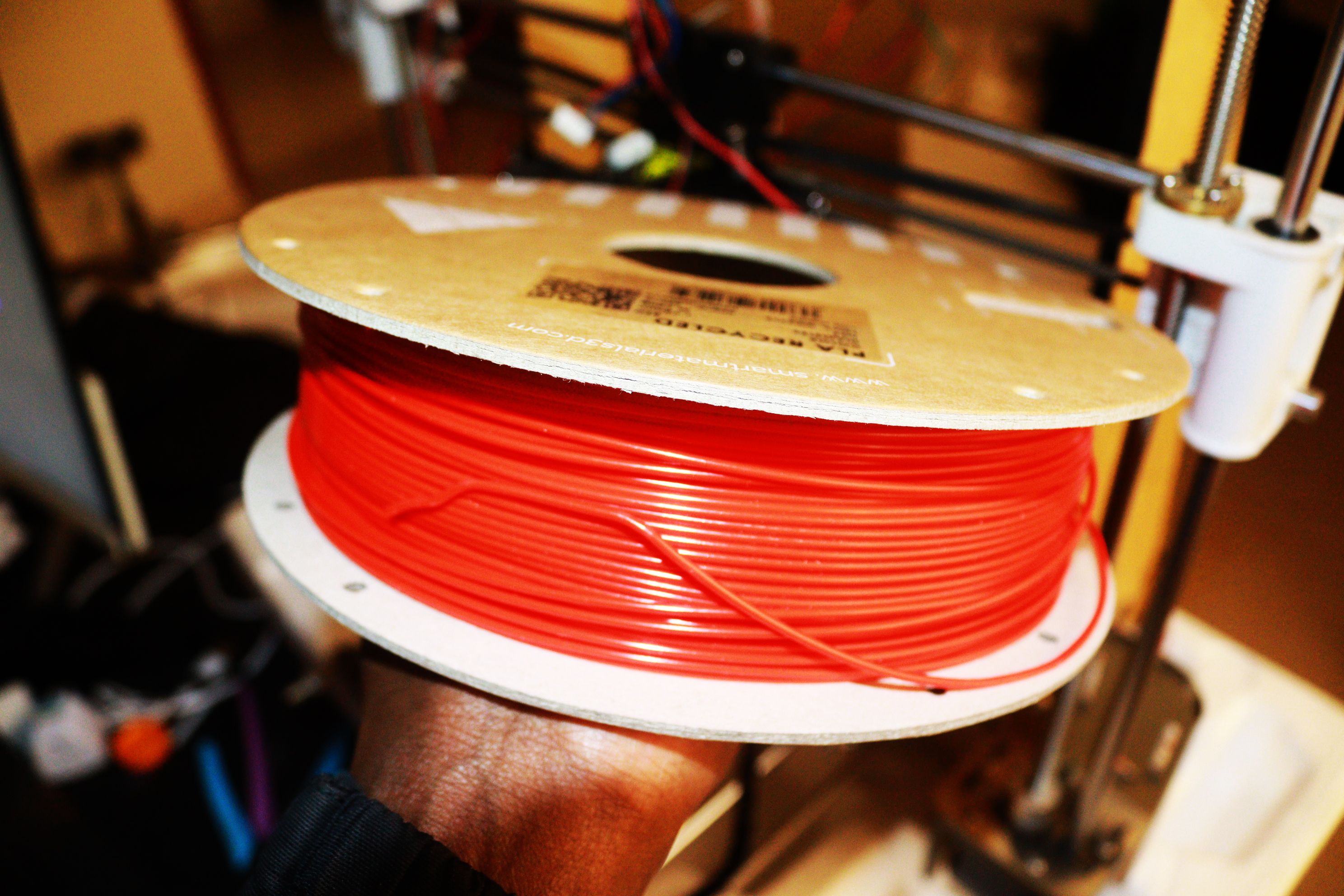

Image Credit: Ricky Impey/YouTube

When using it, place the nozzle on top and wait a few minutes before removing it.

You should be able to see the stuck filament melting away like butter.

Acetone is an excellent solvent that softens and breaks down various materials while being relatively safe and non-toxic.

you might get a 3D printer nozzle in your local hardware store, or you buy it online.

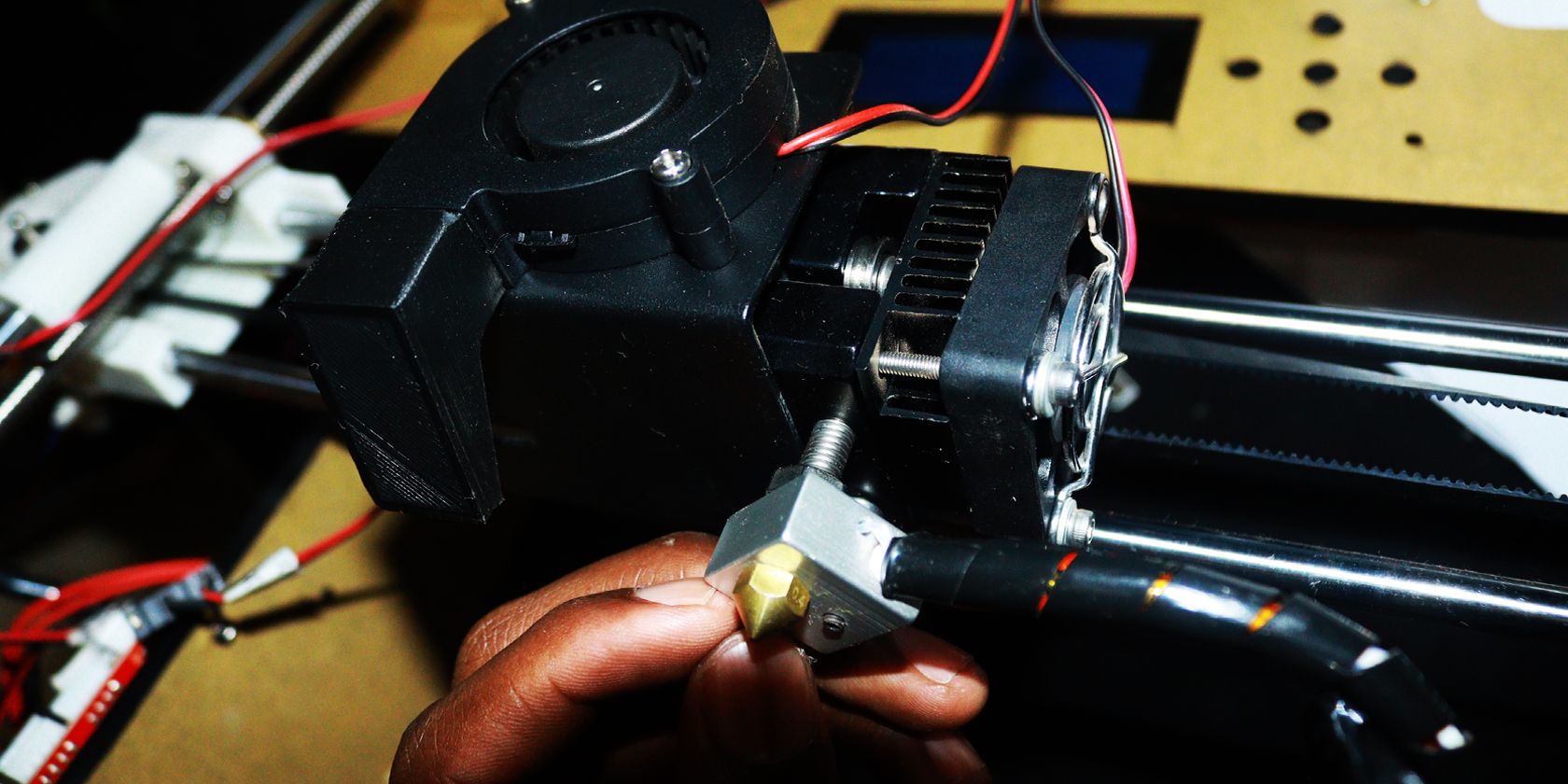

Clean up the extruder and implement the new nozzle with a few drops of oil for lubrication.

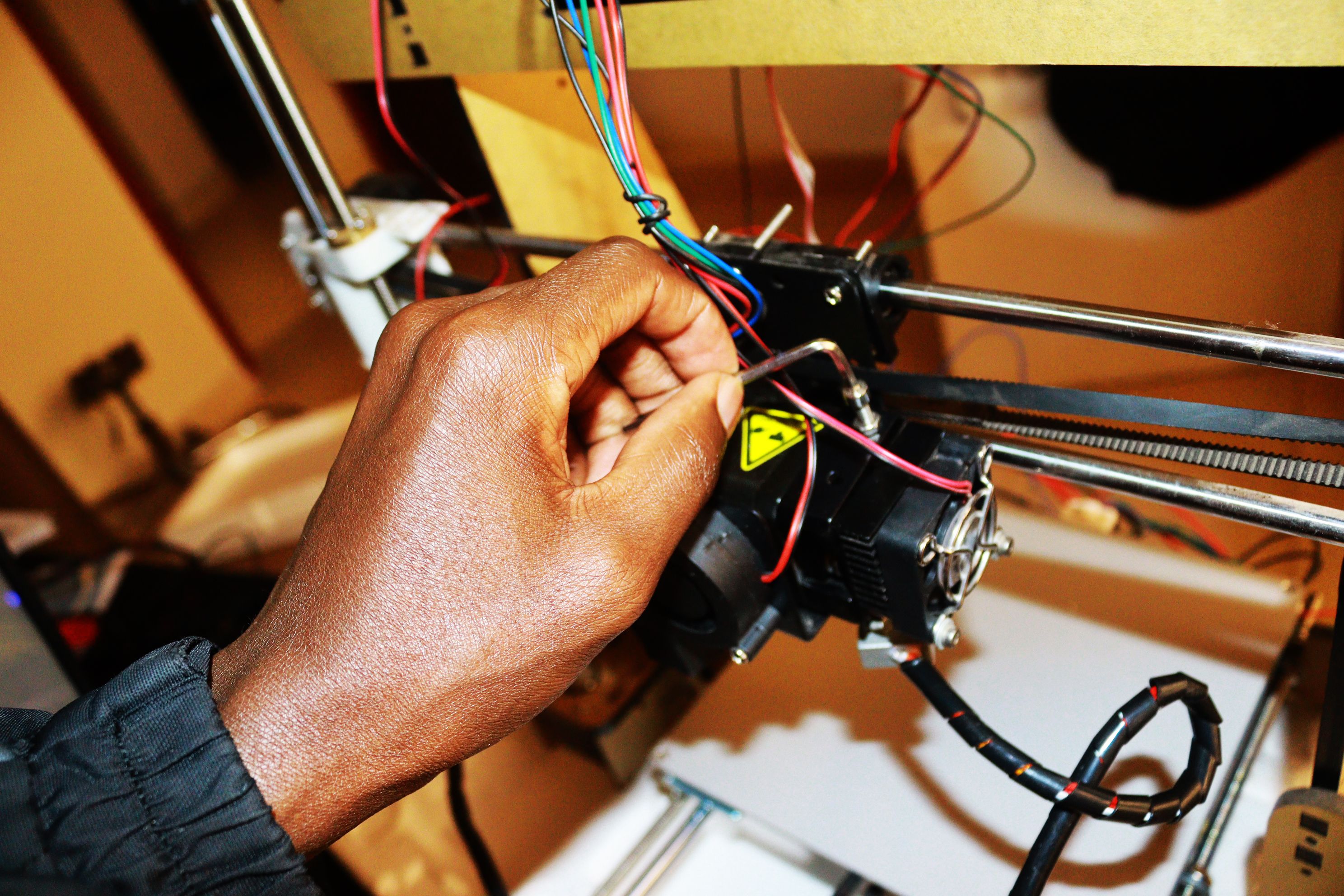

Remember to reattach all pieces at their original connection points before restarting your 3D printer.

Knowing the causes of clogs is the first step in preventing them from occurring.

If you follow the above tips, you should be able to unclog your 3D printer nozzle.

Image Credit: Ricky Impey/YouTube