With the technologys only limitations being budget and user creativity, the number of potential creations is nearly endless.

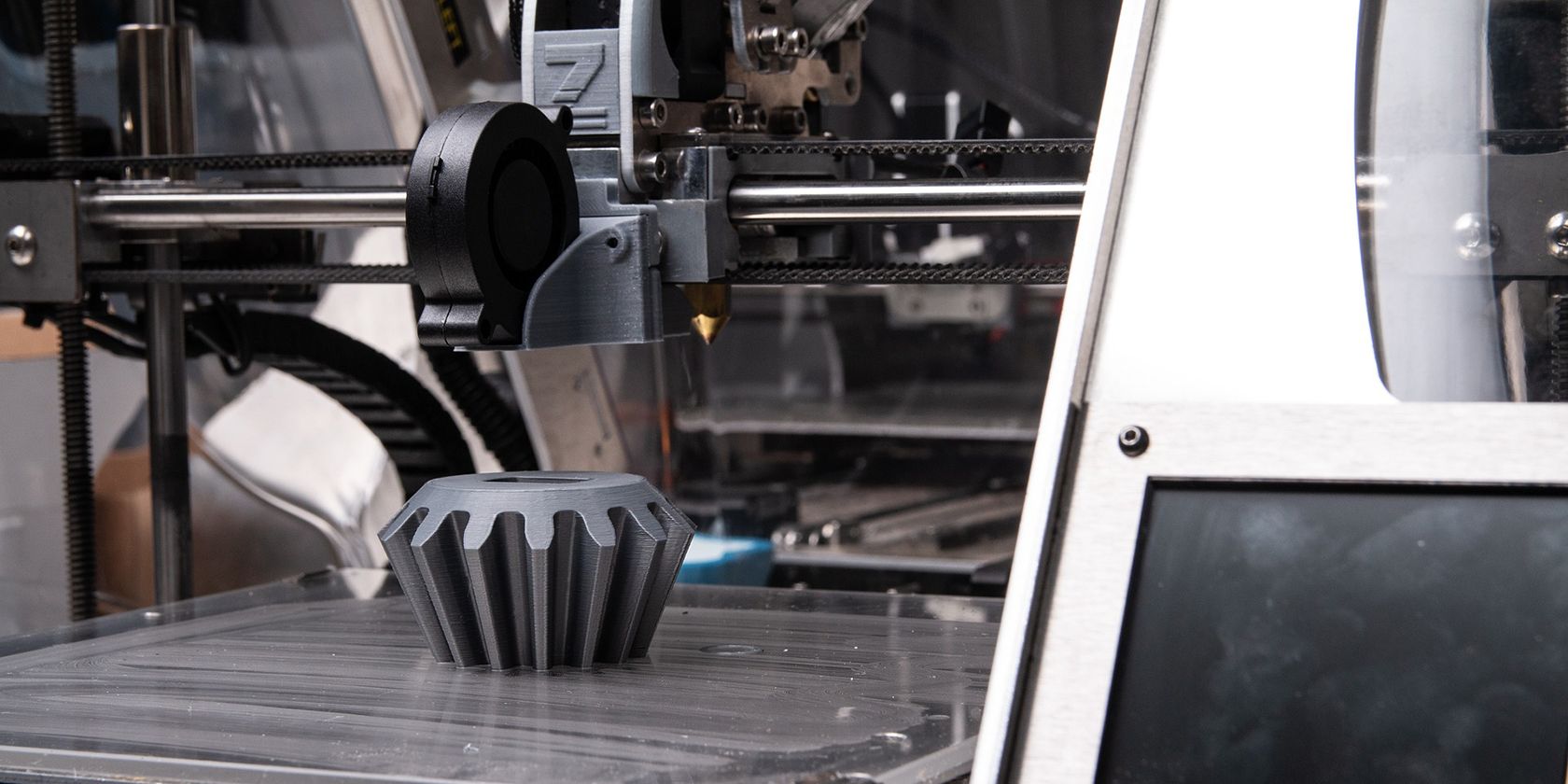

They can create tangible objects by building them up layer by layer.

Using CAD software or 3D scanners, objects can be designed from scratch or recreated.

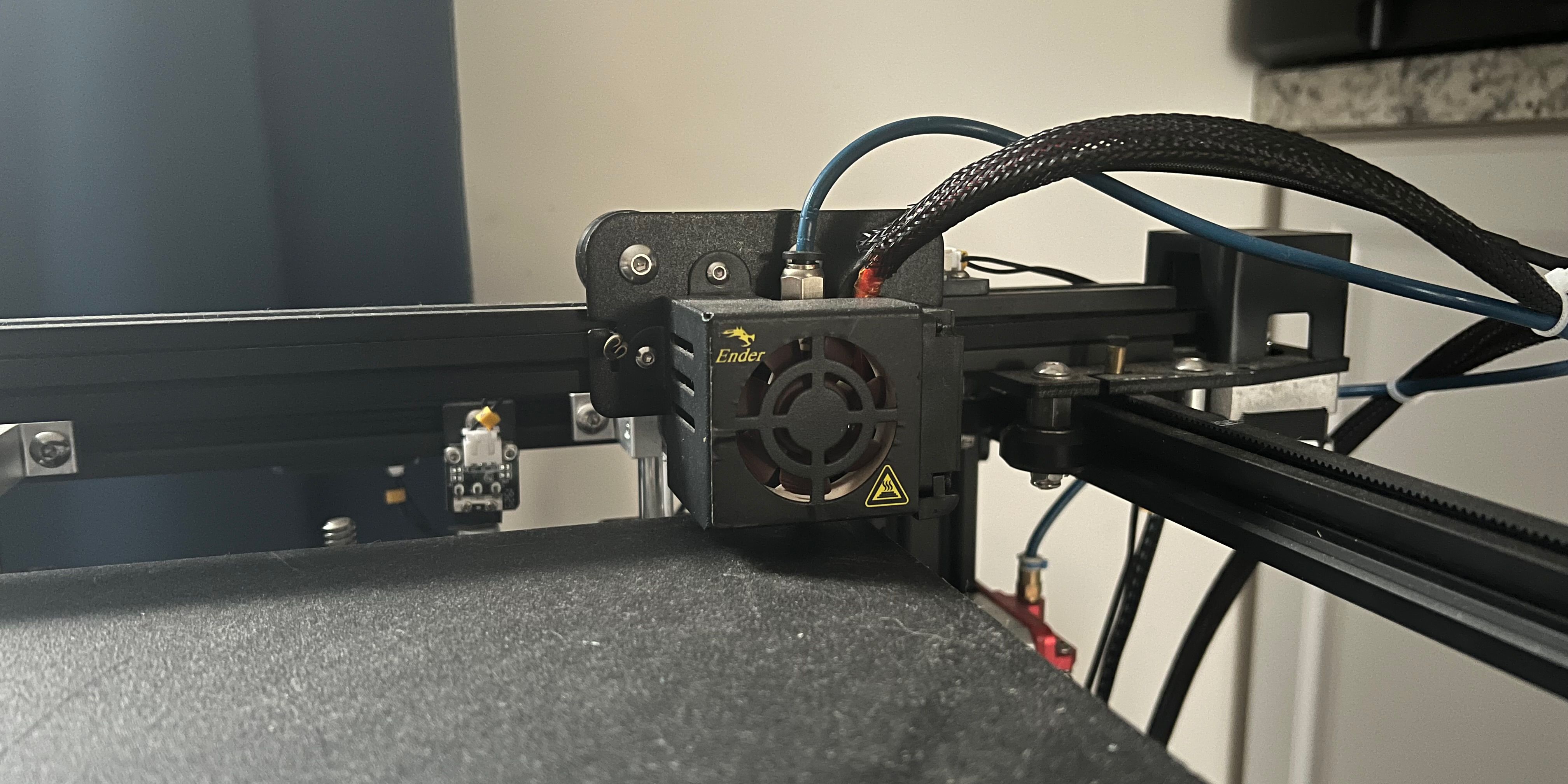

From there, the resulting G-code, OBJ, or STL file can be exported to your 3D printer.

Printed on a bed, it builds up from the bottom to the final model.

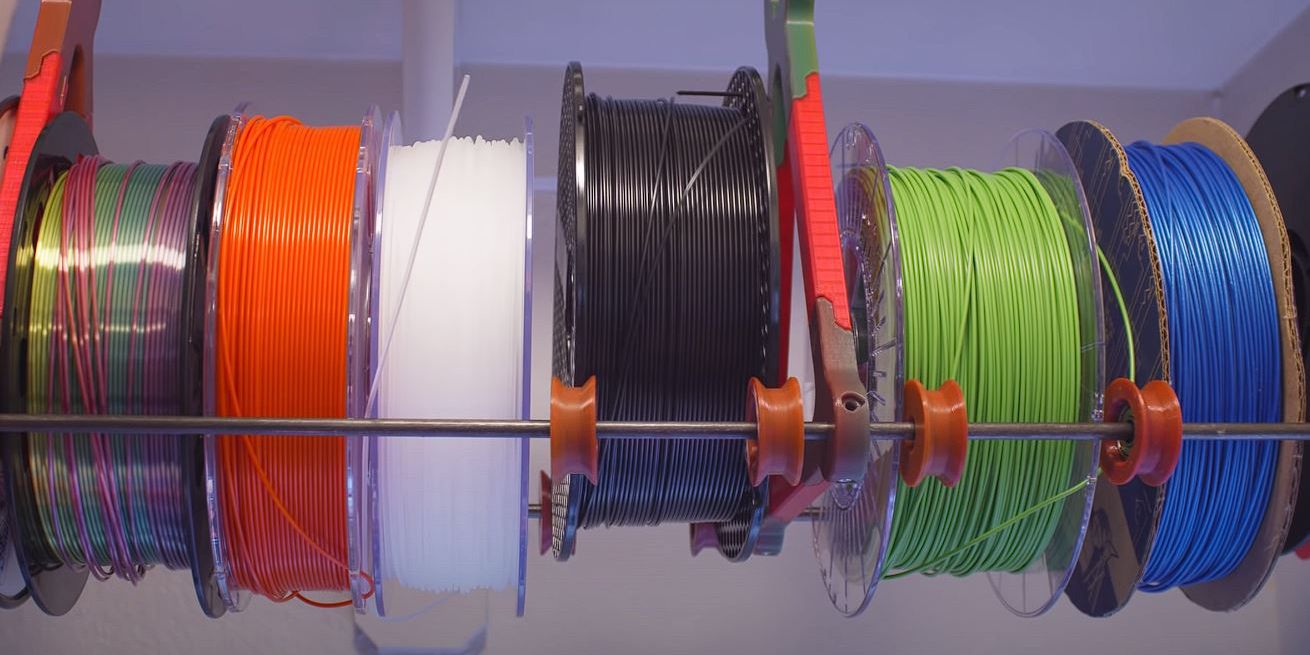

Differences in Filament

An important aspect of 3D printing is the filament you opt to use.

Image Credit: Zack Freedman/YouTube

The lower operating temperature eliminates the need for a heated bed.

Despite the simplicity, there are a few drawbacks to using PLA as your primary filament.

PLA has proven to be flexible and rather fragile, making it more suitable for small models and prototypes.

Image Credit: Zack Freedman/YouTube

Because of its durability, ABS is suitable for high-wear items and automotive trim pieces.

The G stands for glycol-modified, which ultimately makes the final print more precise, durable, and usable.

3D scanners can take the form of your mobile phone or a dedicated piece of hardware.

Parts like connecting rods need to be made from stronger materials such as carbon composite.