Its fast, reliable, and can produce some stunning results.

Still, at under $1000, the P1S and AMS is a superb beginner-friendly package.

A superb beginner-friendly enclosed printer with outstanding software for your smartphone or desktop.

James Bruce / MakeUseOf

Bambu Lab was one of the first companies to produce a commercially available CoreXY printer.

A pair of servos then control the X and Y axes simultaneously.

That doesnt mean its flimsy in any wayquite the opposite.

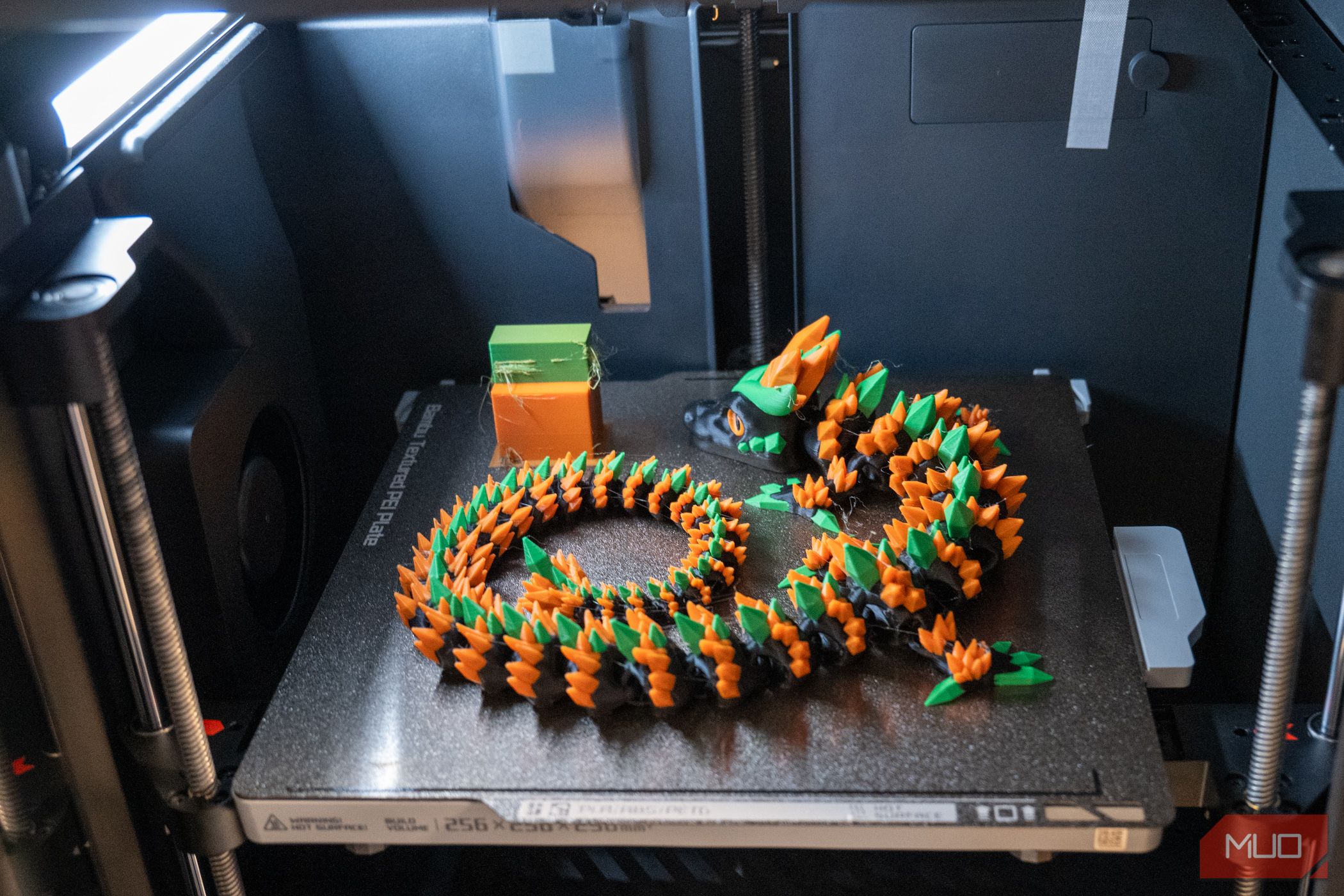

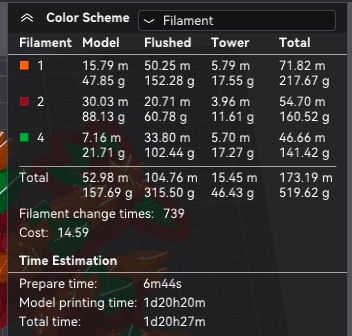

A superb beginner-friendly enclosed printer with outstanding software for your smartphone or desktop. Combined with the AMS (Automatic Materials System), the P1S can produce stunning multicolor prints: up to four filaments can be stored in a single AMS, and up to 4 AMS units can be combined for 16 filament printing. However, you should be aware the multicolor prints produce a lot of waste, and to mitigate that, you’ll need to print either in multiples or print additional “waste” objects to soak up the purged filament.

Its a well-designed and durable structure that minimizes unwanted vibrations.

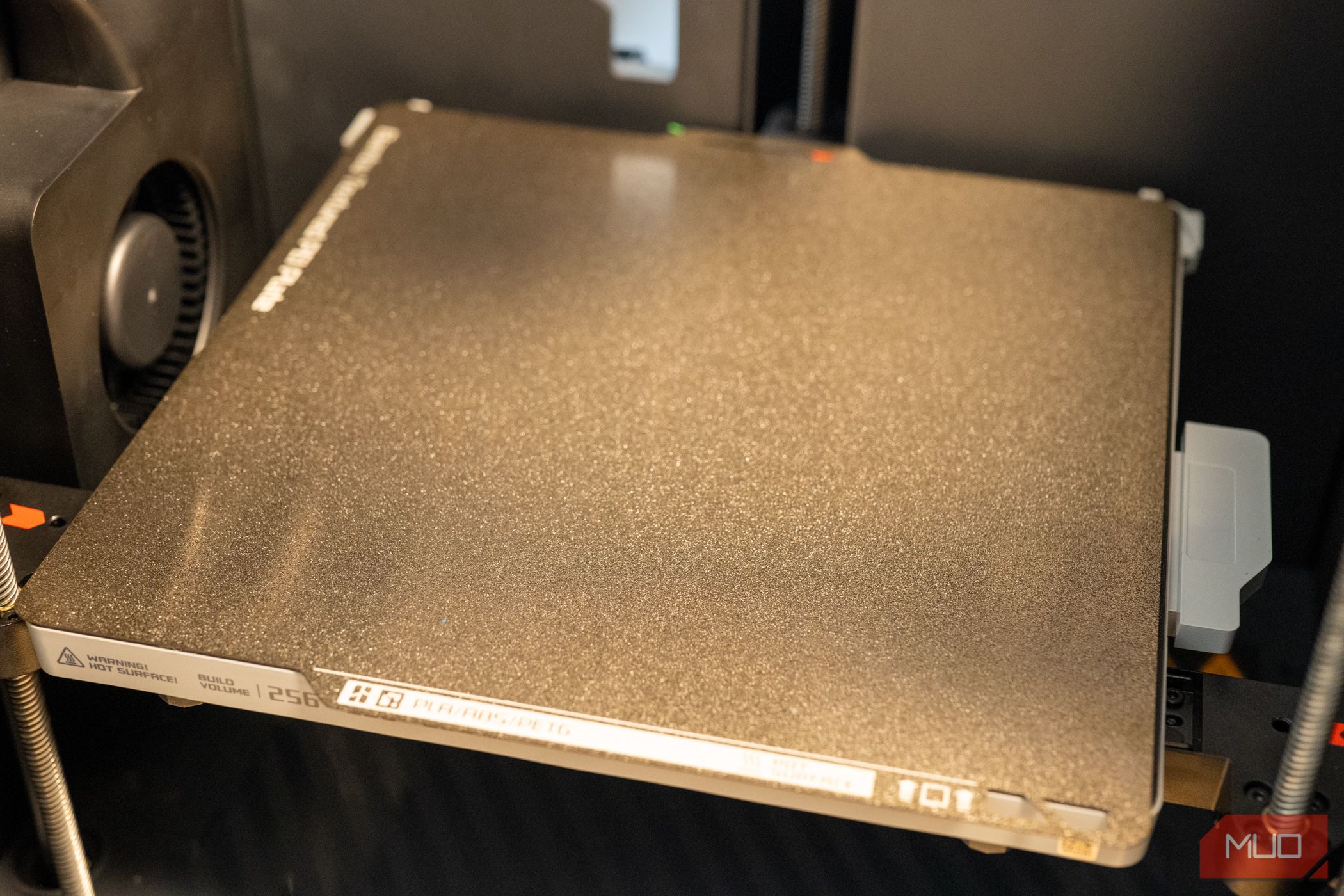

The build plate provided is a general-purpose double-sided textured PEI plate with a lovely golden coloration.

This provides an incredible surface for first-layer adhesion while also letting your print slip effortlessly off once cooled.

A superb beginner-friendly enclosed printer with outstanding software for your smartphone or desktop. Combined with the AMS (Automatic Materials System), the P1S can produce stunning multicolor prints: up to four filaments can be stored in a single AMS, and up to 4 AMS units can be combined for 16 filament printing. However, you should be aware the multicolor prints produce a lot of waste, and to mitigate that, you’ll need to print either in multiples or print additional “waste” objects to soak up the purged filament.

It should handle PLA, ABS, and PETGit had no problem with PLA-CF either.

Practically speaking, this hasnt bothered me at all.

Outside of the initial setup, I haven’t touched the front controller.

James Bruce / MakeUseOf

Regarding noise levels, the P1S runs the gamut of virtually silent to What on earth was that?

High print speeds of up to 500mm/s can also sometimes result in quite a melodic overture.

Most of the time, while printing, it’s quiet enough to have next to my workstation.

James Bruce / MakeUseOf

Made of ABS and acrylic, the lid of the AMS shuts tightly to keep out the ambient air.

Theoretically, you shouldnt have a problem with filaments getting too wet when stored inside the chamber.

That means anyone who regularly churns out models on demand will see a significant productivity increase.

James Bruce / MakeUseOf

That doesnt mean youre locked into their ecosystem, though.

I had no problems mixing and matching filaments during my testing.

While impressive, theres a massive dirty secret to multicolor printing: the sheer amount of waste it produces.

James Bruce / MakeUseOf

The black was fairly efficient, and the green was about twice as much wasted.

This was having applied a few waste optimization methods.

In the example above, the filament needs to be changed 739 times.

James Bruce / MakeUseOf

That number can’t be reduced, so it’s what you do with the purged filament that matters.

But no more so than printing a complex object with lots of supports.

My second multicolor print was aPanda from Flexifactory (free to download).

James Bruce / MakeUseOf

The stand was a separate print and the pandas are articulated.

For this, I cut the waste significantly by simultaneously printing some helpful household clips.

Ive toyed with dual-extruder and dual-filament feed printers before.

James Bruce / MakeUseOf

The AMS module of the P1S hasnt failed me yet, producing incredible results.

In over a decade of covering 3D printers, I continued to be astonished by the progress.

For those, you’ll want to fit the rear spool holder and unplug the AMS.

James Bruce / MakeUseOf

It’s perfect for working with PLA, though.

Thats another huge source of plastic waste, though some manufacturers are increasingly switching to cardboard.

Bambu Lab has gone the other direction, using reusable, durable plastic spools.

Simply twist to unlock the cardboard inner core, and replace with your newly purchased filament.

It would be fantastic to see this reusable spool design open-sourced and used across the industry.

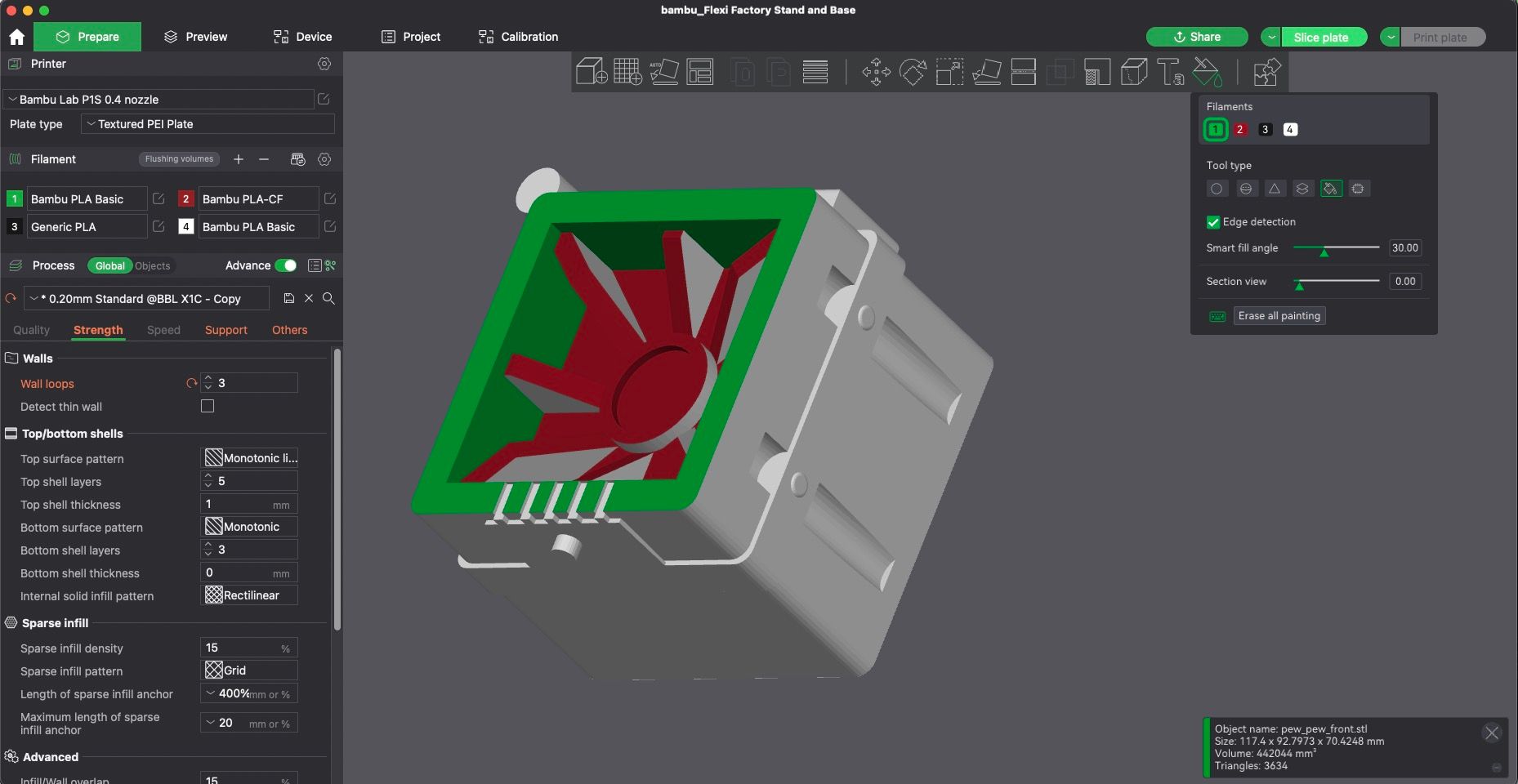

Bambu Lab has produced two outstanding bits of software for desktop or smartphone.

James Bruce / MakeUseOf

On the handset side is Bambu Handy.

It also offers a preview of the current print through the webcam and full remote control capabilities.

For ready-made multicolor models, assigning each part to a different filament or combining subassemblies is easy.

James Bruce / MakeUseOf

you’ve got the option to even add text to models for quick customizationthen paint the text.

It usually offers more features.

In this case, that absolutely isn’t true.

James Bruce / MakeUseOf

Bambu Studio is so good that I’ll find it hard to use anything else again.

It wasnt easy, to put it mildly.

It was ridiculously simple and didn’t require heating up the nozzle at all.

James Bruce / MakeUseOf

I completed the swap in less than five minutes.

Should You Buy the Bambu Studio P1S and AMS?

I’ve not had a failed print.

James Bruce / MakeUseOf

I’ve made multicolor prints effortlessly.

I haven’t spent a week calibrating things.

The software doesn’t fight against me at every step.

It’s like the Apple of the 3D printing world: it just works (TM).

This is what 3D printing was supposed to be.

This is how it looked in the movies.

James Bruce / MakeUseOf

Each change has to be purged somewhere.

You should print functional objects at the same time as multicolor ones to use up that waste effectively.

Still, the environmentalist in me dies a little when I look at the scrap box at the back.

James Bruce / MakeUseOf

I already have a large plastic bag of plastic curls that I don’t know what to do with.

Figuring outhow to recycle PLA wastewill be my next hobby.