While offering some of the best functional elements of filament printing, its trade-offs are limited.

If you’re wanting to learn and enjoy rewarding DIY projects, it’s a great investment.

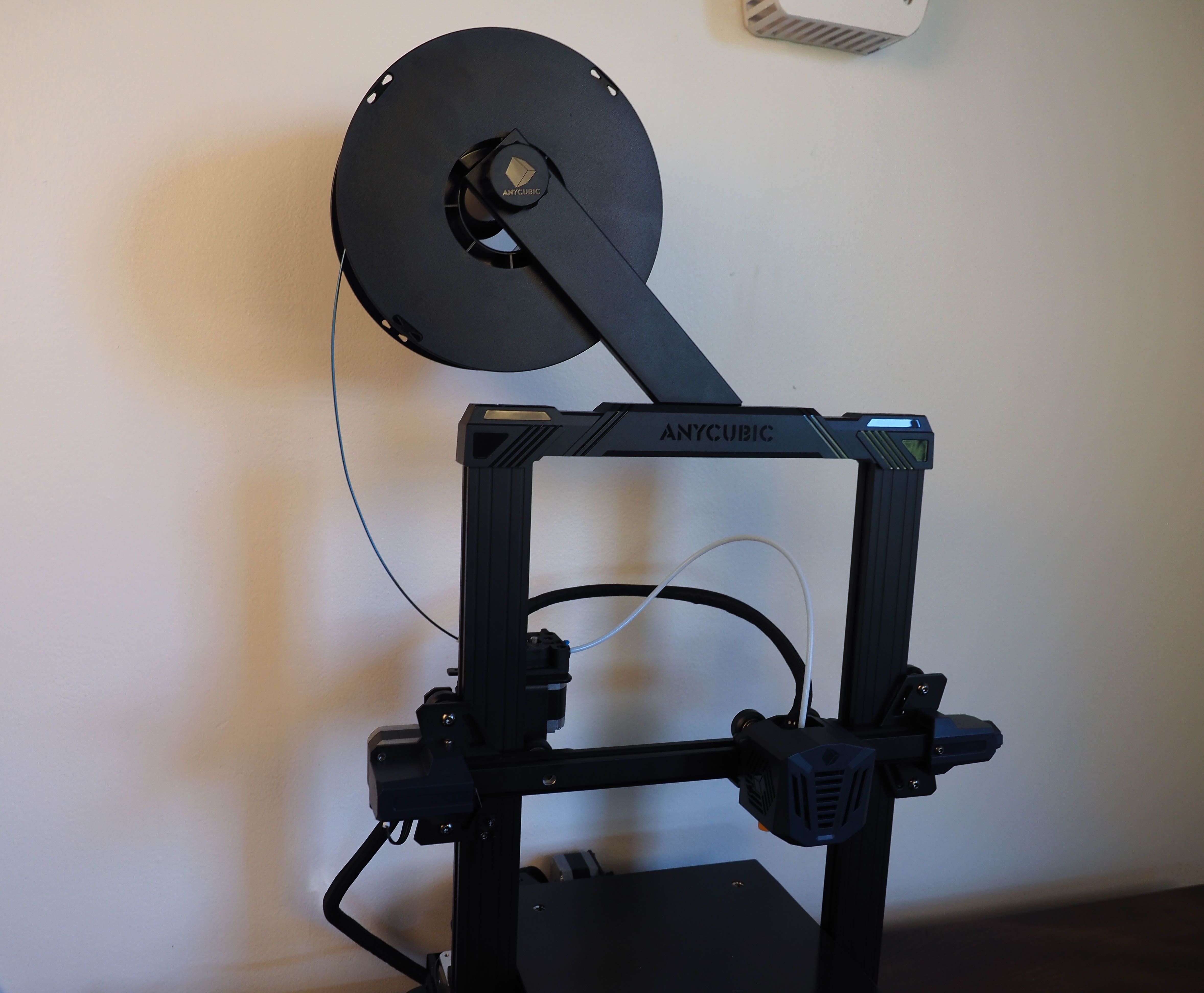

The Anycubic Kobra Go provides an educational introduction to 3D printing.

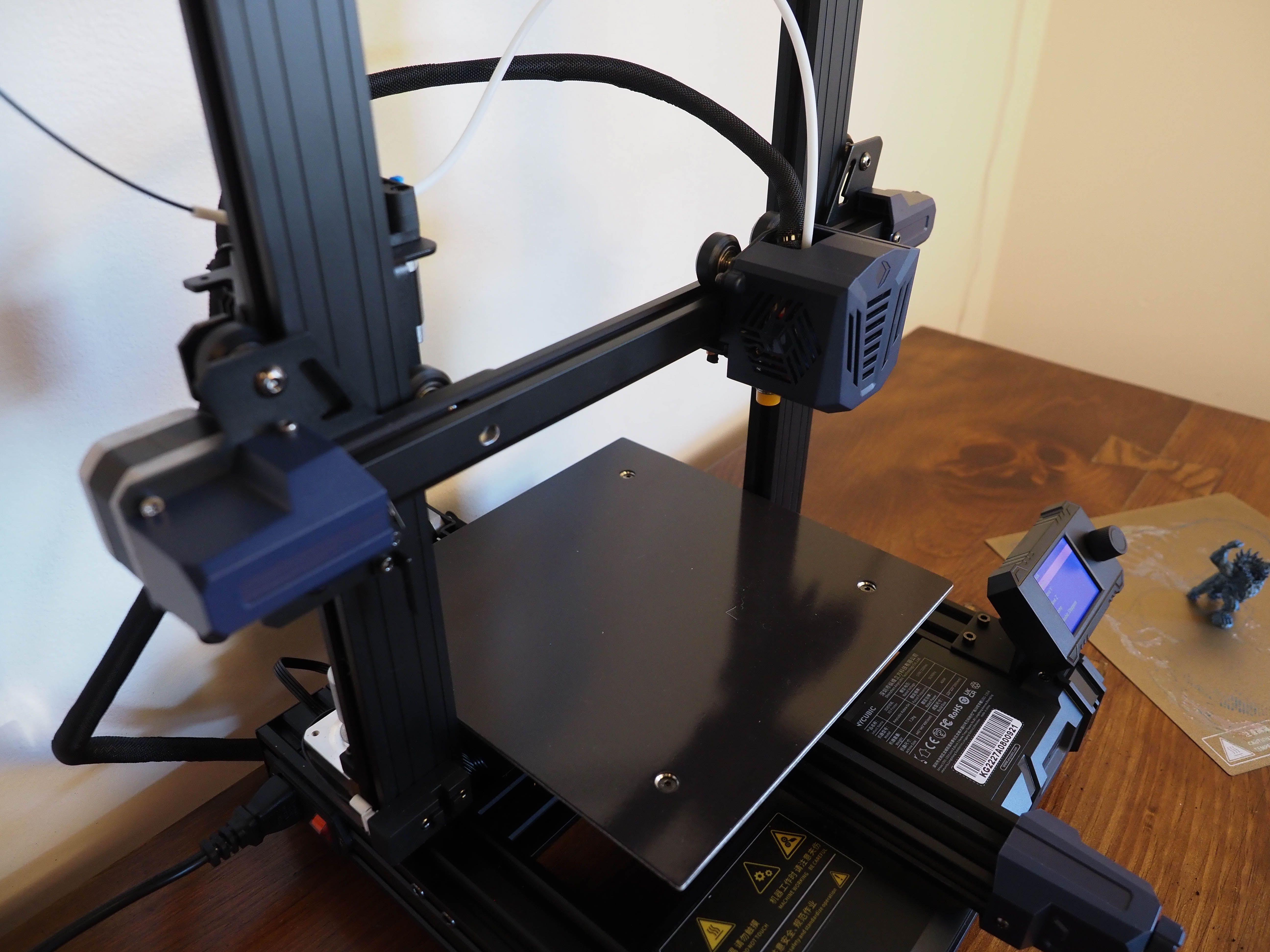

For those already versed in laser engraver or 3D printer assembly, the process shouldn’t be too unfamiliar.

Beyond trying to ensure proper piece fitting, only certain steps hold more difficulty.

Additionally, I felt the wires could have been labeled more precisely for faster installation and less visual double-checking.

Regardless of your skill level, these steps provide an intuitive look at the functionality of the Kobra Go.

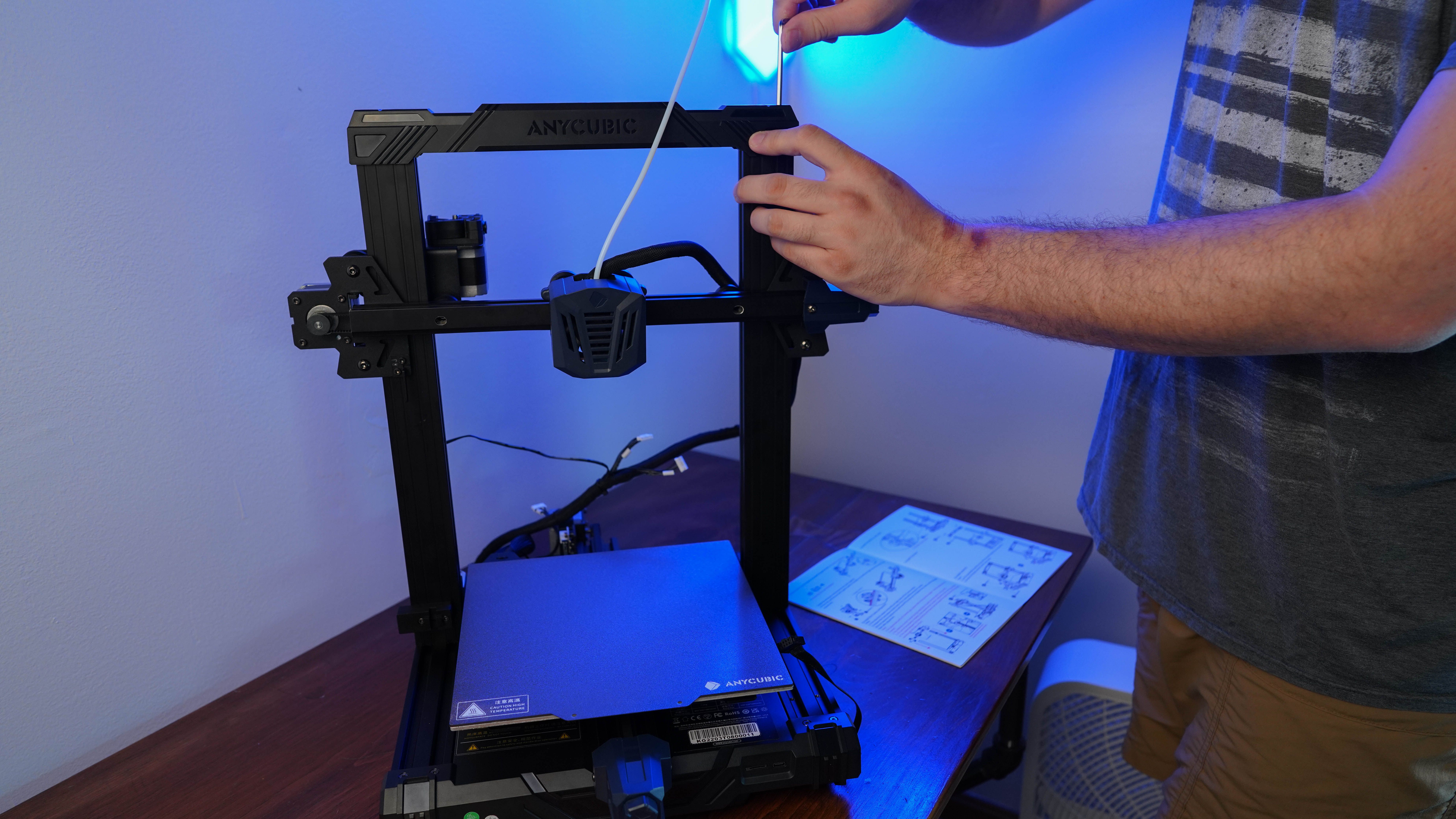

When finished, you’ll calibrate the Kobra Go and make adjustments to the likes of the eccentric nuts.

These steps are quite crucial; you’ll want to minimize wear and tear on your printer’s wheels.

Similarly, you might make belt adjustments via a knob, allowing for easier fine-tuning after set-up.

However, it isn’t a touchscreen; instead, the Go utilizes the knob control exclusively.

While the sizing down won’t be popular with all, it does complement the compact design overall.

The control dial is responsive; there’s not an endless amount of menus to scroll through.

For its limitations, they mostly serve as minor inconveniences in exchange for a lower price point.

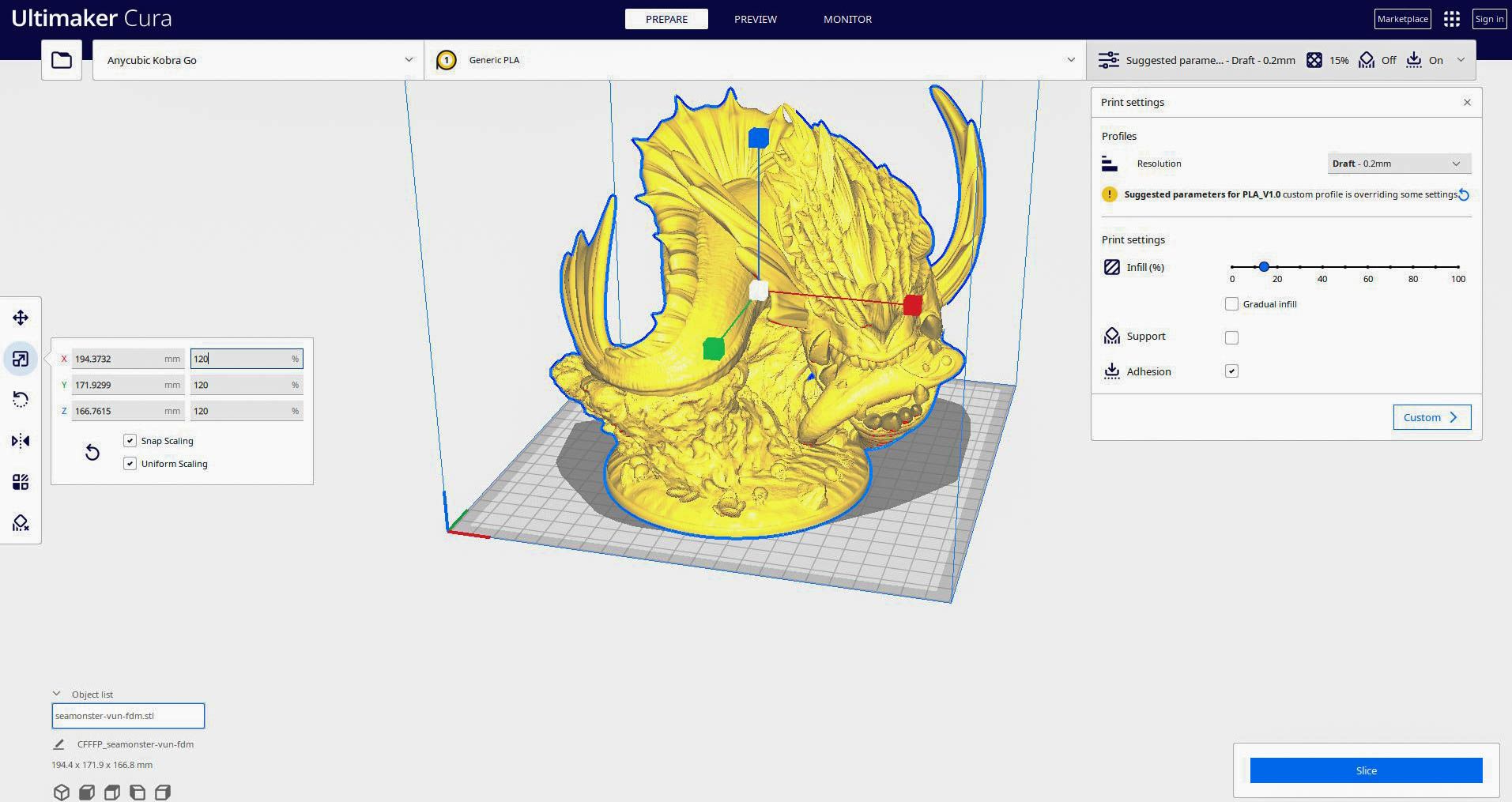

By following Anycubic’s instructions, you’ll set up a custom machine profile for the Kobra Go.

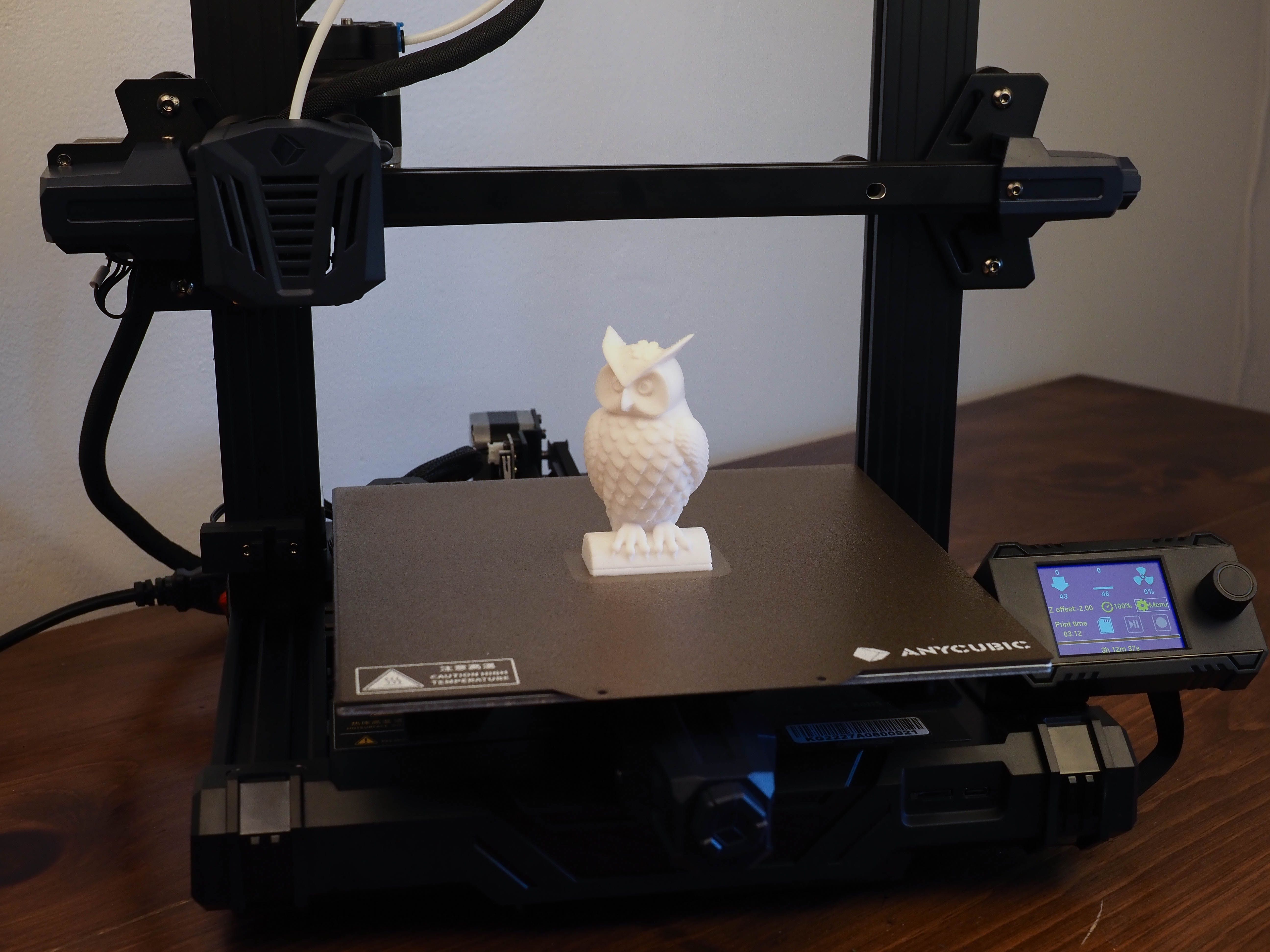

When printing, the Anycubic Kobra Go supports both offline and connected printing.

For online printing, you must first plant the CH340 driver file from the included microSD card.

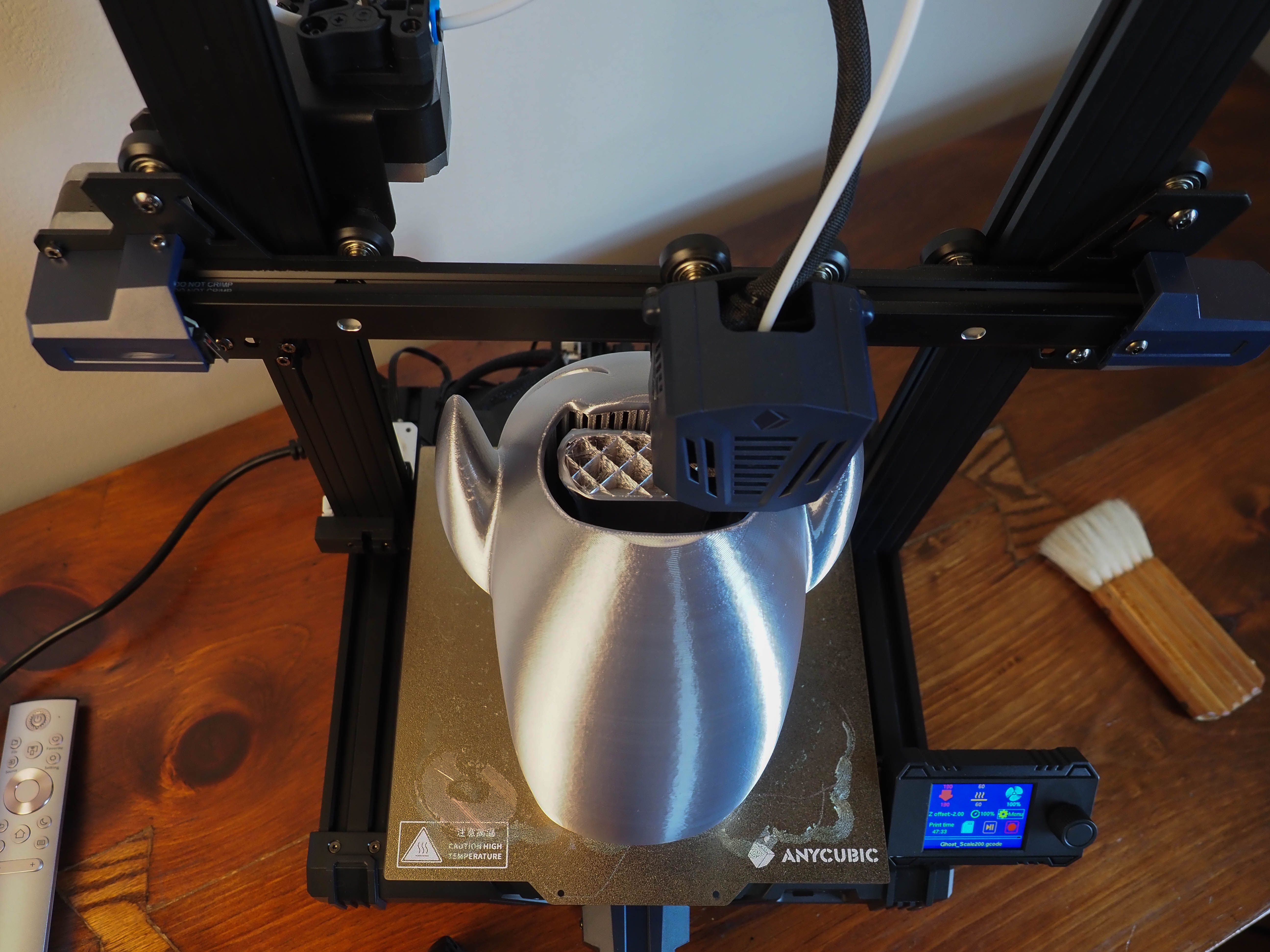

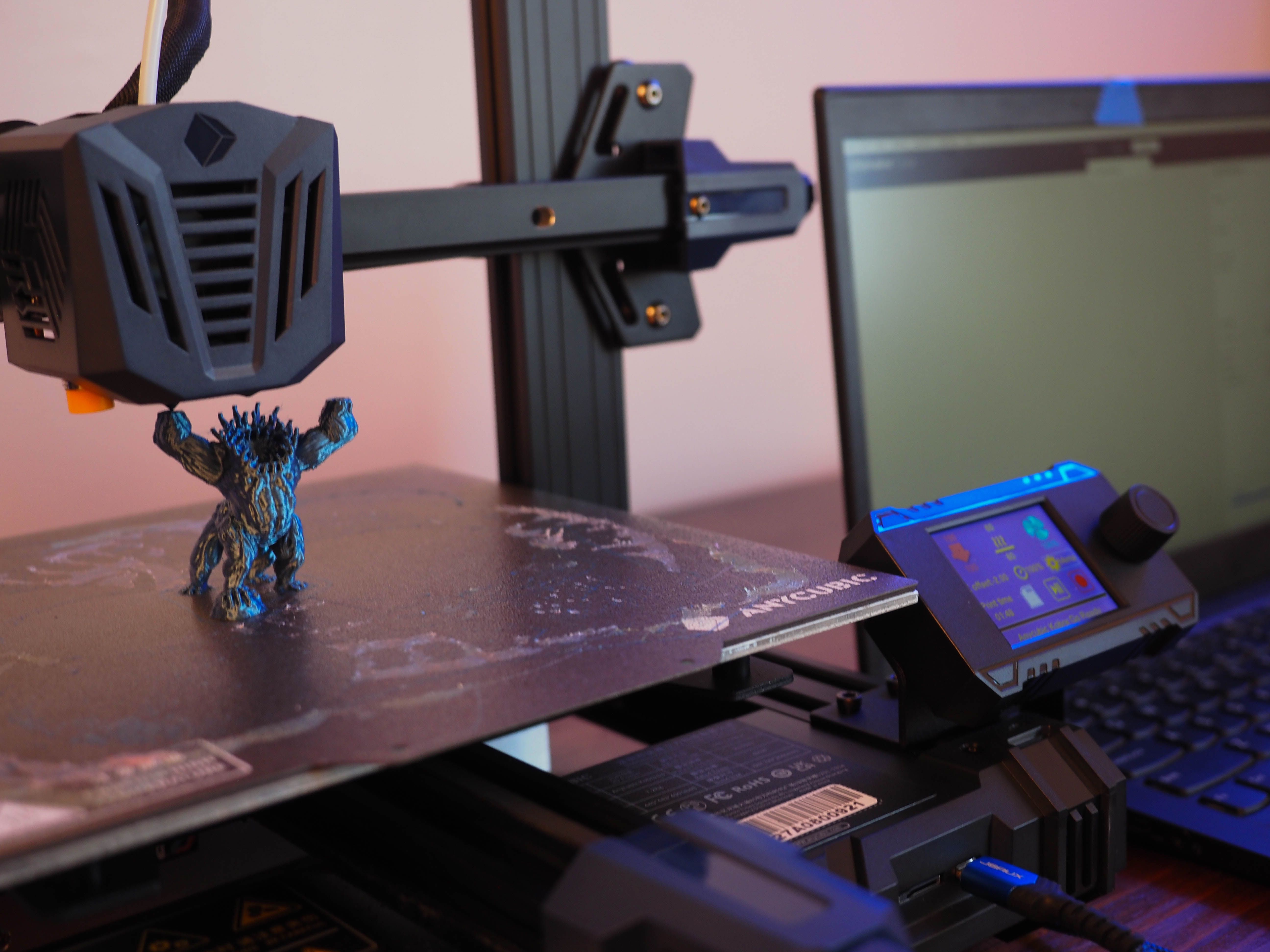

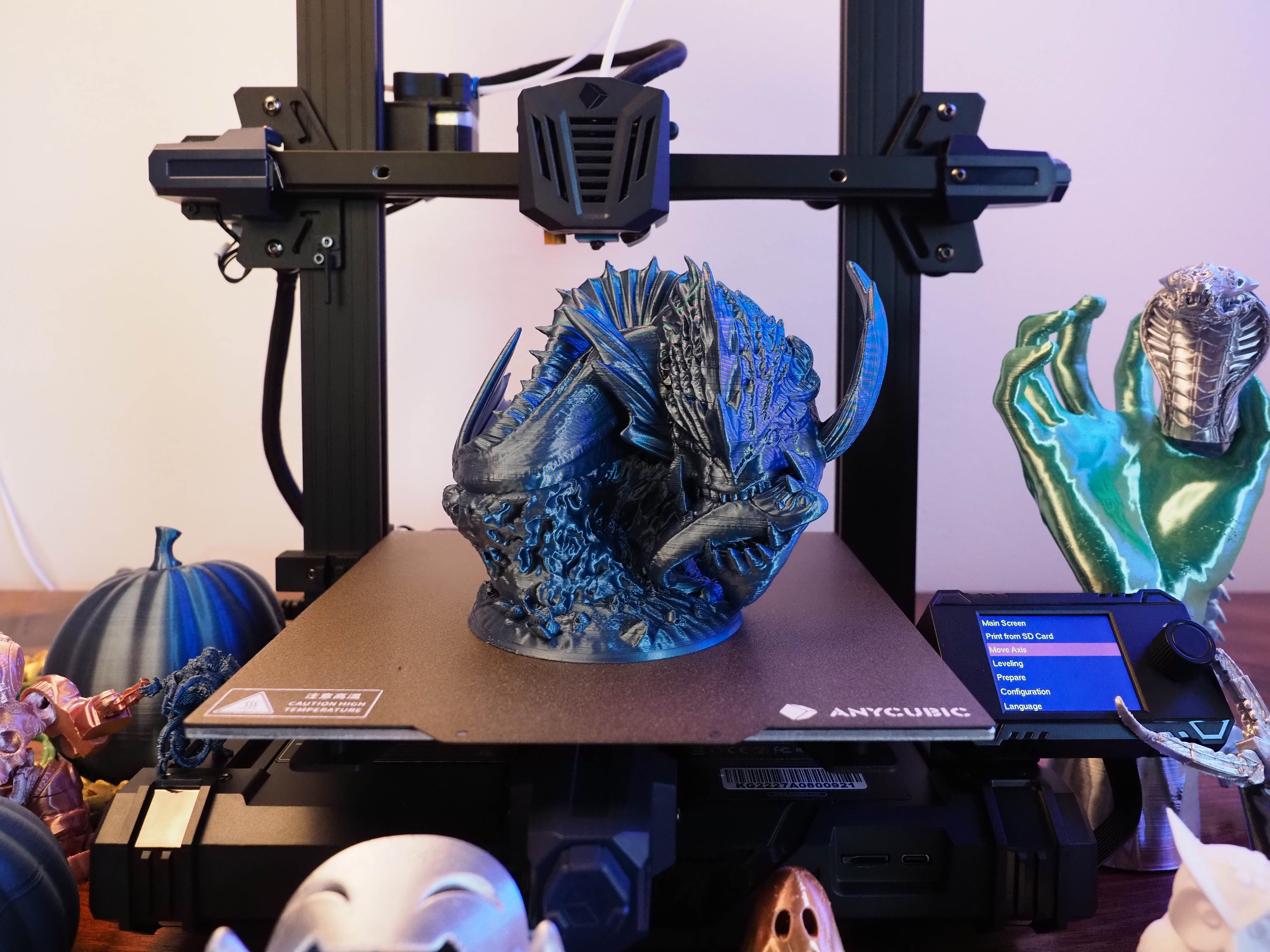

As one would expect, smaller, less complex models usually only take a few hours.

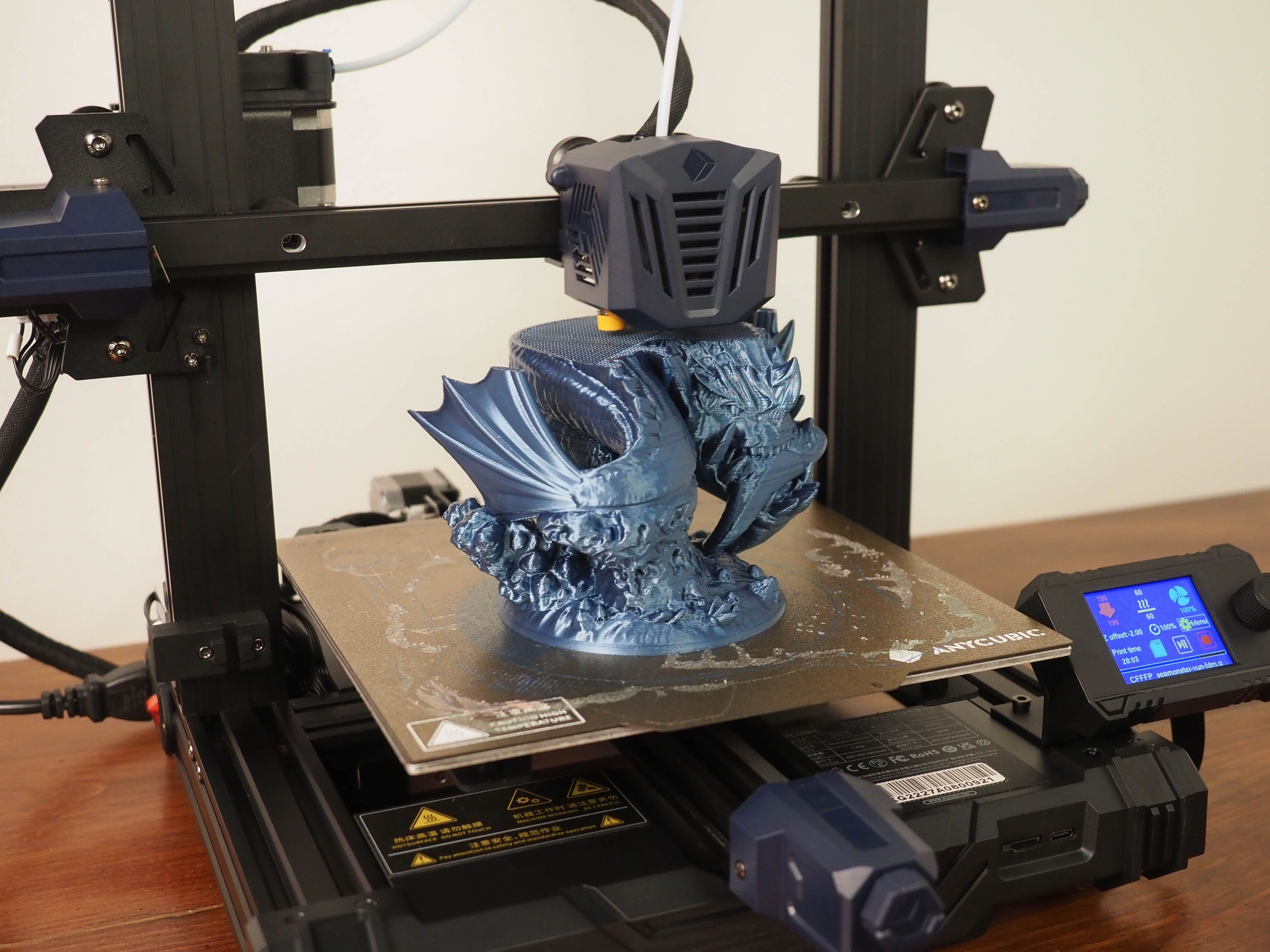

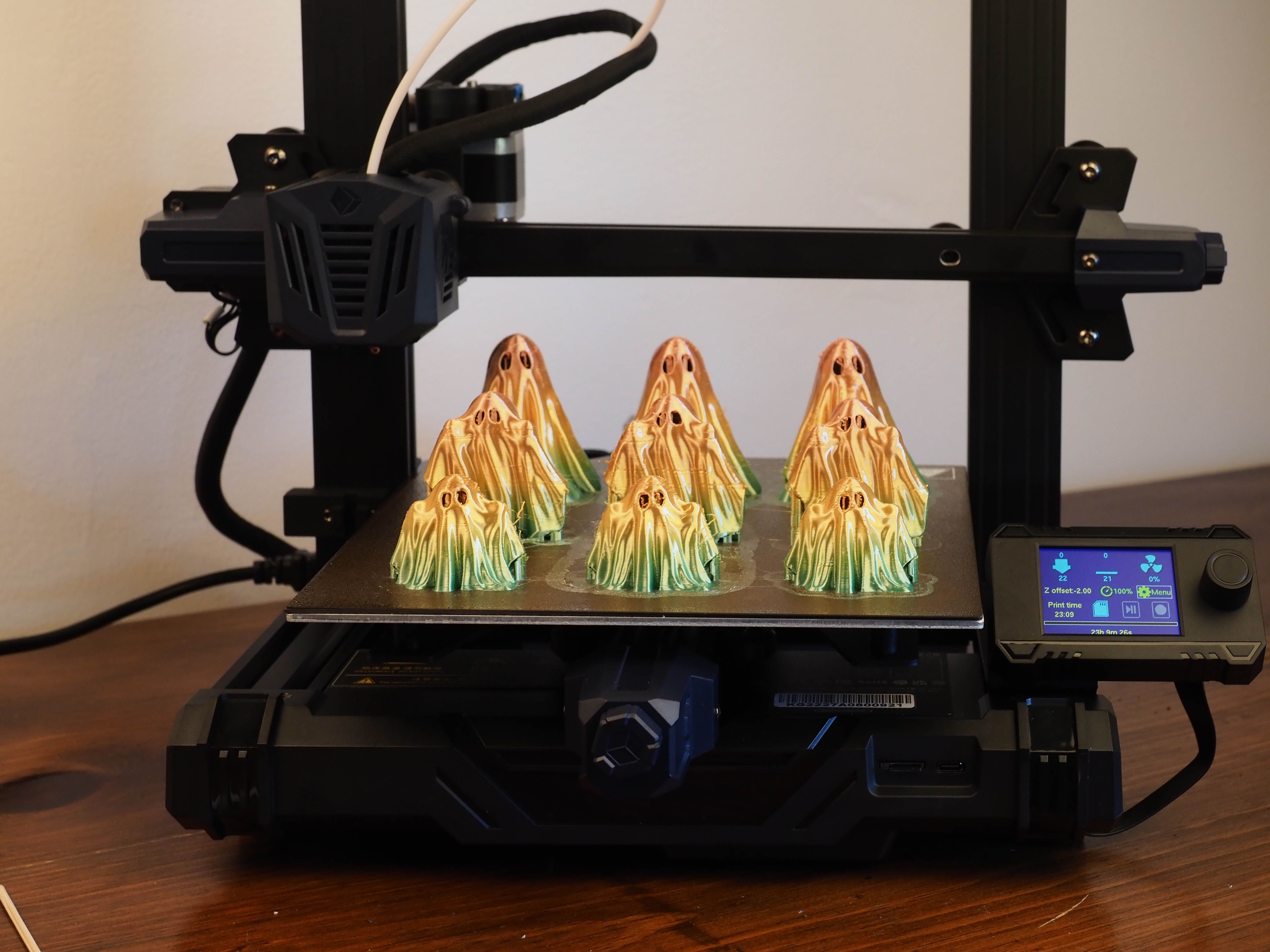

Whereas larger or multi-print models with increased travel time between placements can easily pass a day in print time.

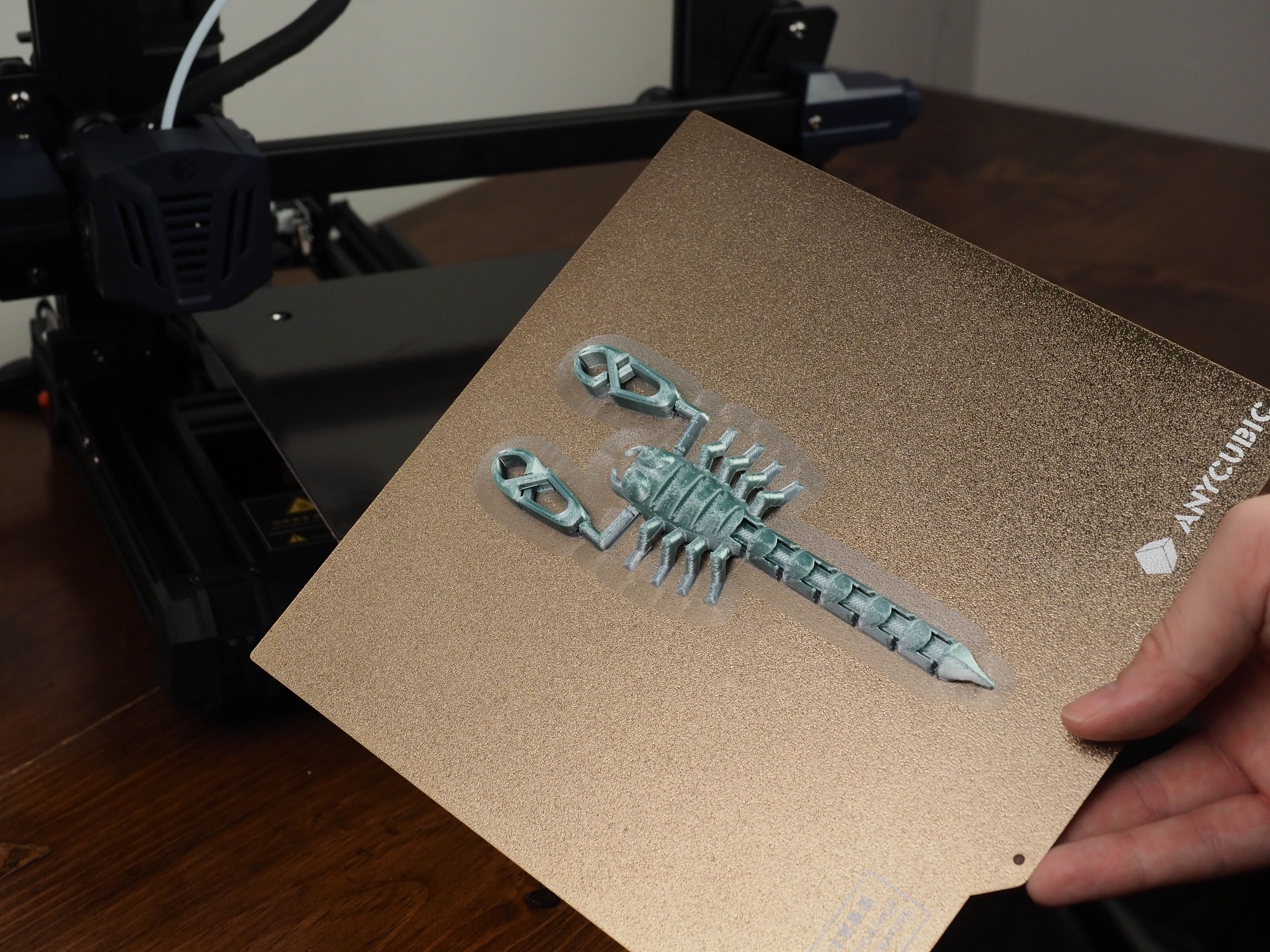

After a print’s completion, the magnetic spring build plate greatly simplifies model removal.

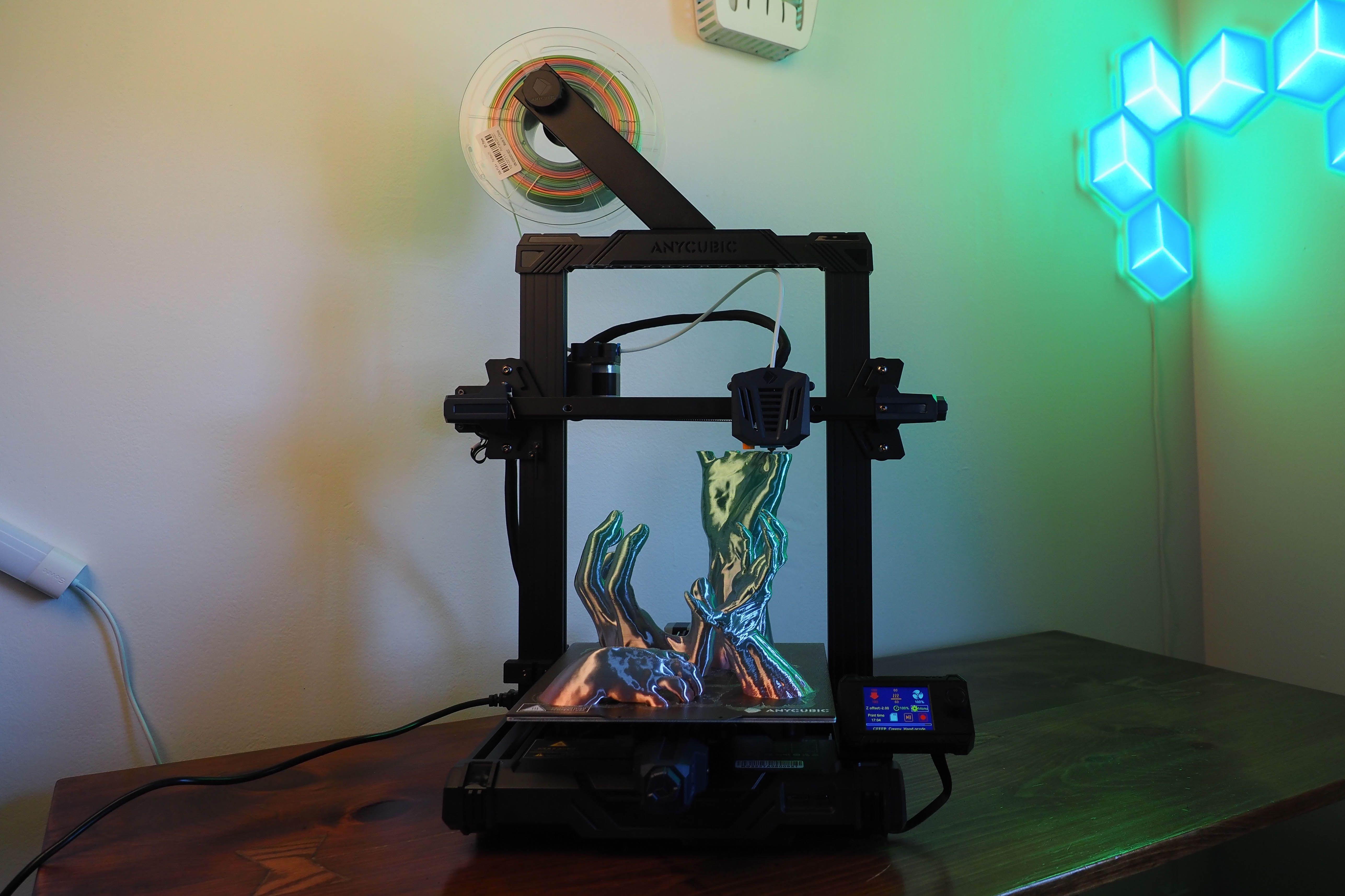

For the period of testing, I used three varieties of Anycubic’s own 1.75mm Silk PLA filament.

Each of these were quite adaptable to different infill configs and provided durable model results.

Despite utilizing a Bowden extruder, I experienced no clogs or serious issues after continual back-to-back prints.

Careful use of configs can remove an excessive need to sand or cut away overly hardened supports.

As I typically printed with the draft profile within Cura, I anticipated more clean-up into painting.

Should You Buy the Anycubic Kobra Go?

Beyond its forgiving price, it tries to offer the essentials without degradation in experience.

Similarly, it’s an excellent option for those with limited space.